how to dimension sheet metal drawings This article will provide a series of key sheet metal design and fabrication guidelines to help engineers and designers understand how to maximize the use of the characteristics of metal sheets, ensuring the feasibility . Tungsten Heavy Alloy Sheets contain 90%-97% tungsten and small amounts of molybdenum, nickel, iron, and copper. Like pure tungsten plate, this alloy product begins as a heated powder, mixed, pressed, and sintered to form a metal alloy .

0 · sheet metal layout drawings

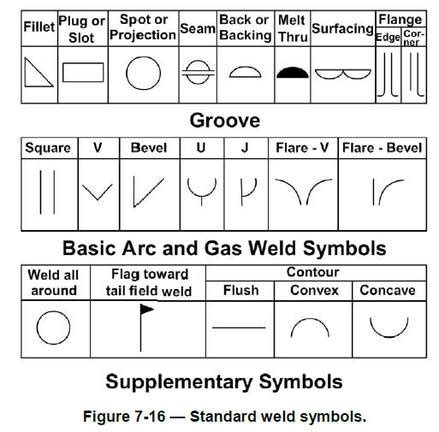

1 · sheet metal drawing symbols

2 · sheet metal dimensioning standards

3 · sheet metal dimensioning guidelines

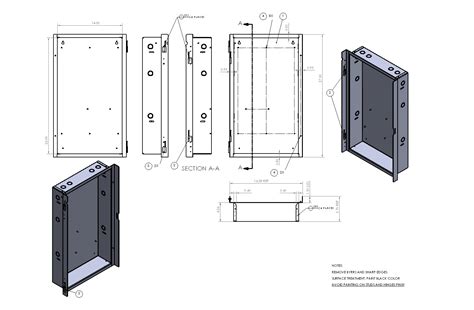

4 · sheet metal diagram fabrication

5 · sheet metal design basics

6 · sheet metal basic drawing

7 · sheet metal basic design guidelines

Level up with a Twinings stainless steel tea scoop for extra precision. Individual products worth £43.00. Our best-loved loose leaf black tea blends (with a tea scoop included, just in case!) You can't beat the classics. English Breakfast, .

This video demonstrates how to properly dimension a sheet metal layout technical drawing. It reviews general dimension standards as well as requirements for.See document 10-0005, Blah Drawing & Drafting Standards and Practices, for the proper setup of a sheet metal drawing. For door panels, front panels, interior panels, and racks see document . This article will provide a series of key sheet metal design and fabrication guidelines to help engineers and designers understand how to maximize the use of the characteristics of metal sheets, ensuring the feasibility .

Generally, dimensioning should be done from a feature to an edge. Avoid feature-to-feature dimensions over two or more planes. Feature-to-bend dimensions may require special fixtures .Learn why you should dimension sheet metal drawings to the formed view, not the flat pattern, to avoid wasting time and money on incorrect measurements. See how bending factors, tooling limitations, and bend angles affect the flat pattern .Sheet metal DFM - design guidelines for formed and punched parts. A first principles look at sheet metal design for manufacturability for experienced engineers. Sheet metal design skills are a crucial tool in any engineer’s .

Sheet metal drawing is not merely a process but an art, where flat metal sheets transform a three-dimensional shape by getting drawn over a die without thinning or altering the sheet’s thickness. This subtle yet complex . Accuracy in sheet metal drawings is paramount as it directly impacts the quality, fit, and functionality of fabricated components. Precise dimensions, tolerances, and material specifications ensure that parts align .

1. Hide/show bend lines. SOLIDWORKS creates a flat pattern sub-configuration for each sheet metal body. Within this configuration are two sketches: one with bend lines and one with the bounding box. Bend lines are . We often hear from customers looking for ways to show Bend Lines on the drawing of sheet metal parts. There are several ways to get Sheet Metal Bend Lines to show (or not show) in a SOLIDWORKS drawing. This . 5. REQUIREMENTS FOR SHEET METAL PART DRAWINGS Sheet metal parts are typically created from material less than .250 inches thick, and are formed by folding the material at specific locations with a controlled bend radius. See document 10-0005, Blah Drawing & Drafting Standards and Practices , for the proper setup of a sheet metal drawing.

sheet metal layout drawings

See more at: http://www.goengineer.com or http://www.goengineer.com/products/solidworks/ or http://www.goengineer.com/govideochannel/Learn about a few featur. Tips for sheet metal design dimensioning . While there are several thumb rules and guidelines for dimensioning the drawings for sheet metal fabrication, we have enlisted a few important and frequently used aspects. Drawings should not have broken geometry when depicting sheet metal parts; Show grain direction in parts made of stainless steel Drawings will need to be converted to a flat pattern for fabrication, however, and 2D drawings are far more useable in sheet metal manufacturing. Where 3D drawings are used, they should be made with a sheet metal module, and good design practices should be followed so that the 3D dimensions match the 2D design.First, check out ordinate dimensioning, it can really clean up sheet metal drawings where you need to show hole locations but don't have space for dozens of stacked dimension lines. With ordinate dimensions, I would be surprised if you need more than two front views for a single part. It still might be crowded though!

When cuts are made into the flat pattern of a rolled sheet metal cylinder (or semi-cylinder), it is not always easy to extract model dimension data in a SOLIDWORKS drawing. Without proper design intent, detailing the flat pattern positions may not work. To draw sheet metal bend lines, first determine the sheet metal bend allowance. The bend line position is determined based on the bend allowance.In the illustration below, the bend allowance is calculated using the formula: inner dimension + inner dimension + compensation factor.. Related reading: Bend Allowance Formula The sheet metal thickness is .

SolidWorks Sheet Metal Drawing Tutorial | Bend Line, Flat Pattern, Unfolded, Bend Table, Punch Table. This tutorial show how to create production drawing for.

When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal part. You can create *.dxf files of sheet metal flat patterns without creating a drawing. Contents. Accuracy in sheet metal drawings is paramount as it directly impacts the quality, fit, and functionality of fabricated components. Precise dimensions, tolerances, and material specifications ensure that parts align correctly, preventing costly errors in manufacturing. With accurate drawings, the fabricator or machine operator can punch in holes . In this article, we will walk through the key dimensions, notes and tables using the NIST example. Figure 1. A sheet metal part example. (Image courtesy of NIST.) First of all, it’s important to emphasize that you can define a sheet metal part or assembly in a way similar to other 3D models using PMI tools such as DimXpert and reference .

2. Dimension datum of parts. Datum: select a group of geometric elements on the part as the basis for determining the mutual position relationship of other geometric elements. According to different purposes, the benchmark is divided into design benchmark and process benchmark. Design datum: the datum used to determine the exact position of the part in the .Don't dimension to a flat pattern, unless a manufacturer specifically requests it. Since it's impossible to form a perfectly sharp corner on a sheet metal part, each bend will be formed with a .

Call out the thickness, and apply a tolerance. In most cases, you can design sheet metal parts such that the thickness tolerance is not critical. Sheet metal fabricators know their sheet metal guages. They can read your numbers, and select the correct sheet from stock. Your inspectors may or may not know sheet metal guages. It is irrelevant to . Although we live in a 3D world, for many the 2D drawing still rules the roost. Inventor provides a set of tools specific to creating Inventor Sheet Metal drawings. Inventor Sheet Metal Drawings. When creating drawing views of sheet metal models you can select the Folded Model .

sheet metal drawing symbols

SOLIDWORKS Sheet Metal Properties can be added to Drawings using a predefined annotation or selectively using standard annotation property mapping syntax. The secret is the annotation MUST be attached to the Flat . In this video tutorial you can learn How to create Sheetmetal Flat state automatically and manually + How to manage Bounding Box dimensions for Flat State mo. Sheet metal is metal formed by an industrial process into thin, flat pieces. Sheet metal is one of the fundamental forms used in metalworking and it can be c. Table of Contents. 1 5 Ways to Optimize Drawings for Precision Sheet Metal Fabrication Services. 1.0.1 1. List part numbers, not just the part name; 1.0.2 2. Use the exact hardware name when possible; 1.0.3 3. Provide details for revision control

This tech tip covers how to add dimensions as a custom property in SOLIDWORKS Sheet MetalCheck out more tech tips at https://trimech.com/blog?tag=3d-cad#soli. Is it possible to create a drawing that has both view fold and the unfolded sheet metal view in the same drawing in Fusion 360? Add both the Flat Pattern and the Folded Model in the drawing views. Create a flat pattern inside the design space. Create a new drawing from the design: File > New Drawing > From Design Select "OK" in the drawing Dialog. Place the .I use ordinate dimensioning on most of my drawings for sheet metal, and try to stick with a few simple rules: keep the text off of the part, keep dimension lines off the part where possible, try to minimize crossing of dimension lines. . If your company has drafting standards you need to follow those, but if you are able to only dimension .

Sheet metal design reviews and drawing preparation. As with any design, mistakes are inevitable. At Five Flute we’re big fans of what we call a continuous design review process. Basically this means running lots of small design reviews so that issues are discovered early before designs develop inertia from integration, and are more costly to . #solidedge #solidedgetutorials #siemens #solidedge2023 In sheet metal bending parts we have to give bending views and bending angle of every flange. From thi. I want to programatically add general dimensions to several Inventor 10 drawings created from sheet metal flat patterns. The features that require dimensions are lines on the Visible Edges and Sheet Metal Bend Centerlines layers. How do I iterate through the collection of features on these layers to determine line start and end points that I can use to create the . 2. Add outer dimensions to a new drawing. Drew can now add outer dimensions immediately after a new drawing. When you have a round part, we’ll add diameter dimensions. If you have a sheet metal part, we’ll add a thickness dimension. In all other cases, we add horizontal and vertical dimensions.

attaching wooden shelves to metal enclosure

attic electrical box cover

Enjoy a collection of perfectly cut and colored genuine gemstones. Don't miss out on our Morganite and Tanzanite colored Quartz pieces! We also have spotless Mexican Turquoise .

how to dimension sheet metal drawings|sheet metal basic design guidelines