best way to make a sheet metal box water proof Sheet metal enclosures can be designed to meet the requirements of NEMA Types 1, 2, 4, 4X and 5. However, if your enclosure requires immersion in water, this is not the best . The extra-deep cabinet has a hanging rod that supports up to 90 lbs, making it ideal for bulky ski jackets, hunting gear, motorcycle gear and more. This heavy-duty steel cabinet is as tough as it looks and, like many Gladiator® products, is backed by a 10-year limited warranty.

0 · sheet metal box steps

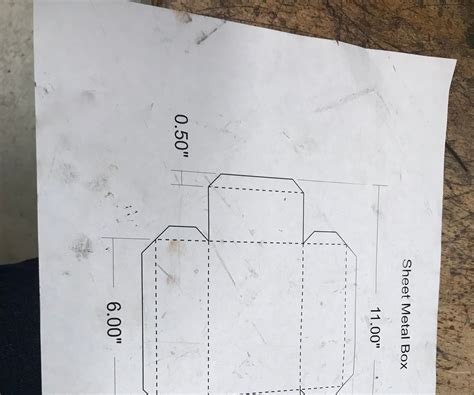

1 · sheet metal box instructions pdf

2 · sheet metal box design template

3 · make your own sheet metal box

4 · how to make sheet metal

5 · how to make a metal box

6 · how to cut sheet metal box

7 · how to bend sheet metal box

Keep your office running smoothly with this WorkPro lateral file cabinet. There's plenty of room to store documents, and the drawers fully extend to help you reach items way in the back. This reinforced, metal multi-drawer file cabinet is complemented by full-width hardware that add a designer touch and magnetic file holders to help make it .

In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my . Sheet metal enclosures can be designed to meet the requirements of NEMA Types 1, 2, 4, 4X and 5. However, if your enclosure requires immersion in water, this is not the best .

A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal . Creating a waterproof enclosure involves more than just choosing the right materials—it’s about mastering design elements like IP ratings, gaskets, and screws to ensure top-notch performance. Discover essential strategies for . This is another great beginner sheet metal project I use in my shop classes. I use it to teach print reading skills and order of operations to my students. .

My containers are made from old license plates and as such have holes in them, but as you can see, the corner is water tight. This technique can be used to make custom sized cookware, condensate pans for AC's and even water troughs for livestock.In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my two previous sheet metal Instructables.

Sheet metal enclosures can be designed to meet the requirements of NEMA Types 1, 2, 4, 4X and 5. However, if your enclosure requires immersion in water, this is not the best choice for you. Here are some guidelines: NEMA Type 1: We recommend a simple two-piece enclosure style that is fully covered on the top of the case.

A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on. We're not going to touch upon bend radii or bend allowances, but these. Creating a waterproof enclosure involves more than just choosing the right materials—it’s about mastering design elements like IP ratings, gaskets, and screws to ensure top-notch performance. Discover essential strategies for achieving superior protection and functionality in this guide. This is another great beginner sheet metal project I use in my shop classes. I use it to teach print reading skills and order of operations to my students. .

_____My Favourite Tools (Through Amazon Influencer Shop): https://www.amazon.com/shop/depyrol_____Podcast:https://i.

I'Ll Show You How To Make a Very Sturdy Sheet Metal Fabrication Enclosure That Is Easy To Build And Can Last For Decades. Why Should You Care About The Material You Use To Make Your Enclosures?You can make watertight trays from flat sheet metal without soldering or riviting. Take a sheet of metal whose length is the length of the finished tray plus two time the height of the sides; Here are steps you must take to waterproof your metal building. Seal interior walls. Rain and snowmelt can seep, drip, or flow through cracks or air leaks in the exterior walls. Moisture can also infiltrate your structure through the .My containers are made from old license plates and as such have holes in them, but as you can see, the corner is water tight. This technique can be used to make custom sized cookware, condensate pans for AC's and even water troughs for livestock.

In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my two previous sheet metal Instructables.

Sheet metal enclosures can be designed to meet the requirements of NEMA Types 1, 2, 4, 4X and 5. However, if your enclosure requires immersion in water, this is not the best choice for you. Here are some guidelines: NEMA Type 1: We recommend a simple two-piece enclosure style that is fully covered on the top of the case.A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on. We're not going to touch upon bend radii or bend allowances, but these. Creating a waterproof enclosure involves more than just choosing the right materials—it’s about mastering design elements like IP ratings, gaskets, and screws to ensure top-notch performance. Discover essential strategies for achieving superior protection and functionality in this guide.

This is another great beginner sheet metal project I use in my shop classes. I use it to teach print reading skills and order of operations to my students. .

_____My Favourite Tools (Through Amazon Influencer Shop): https://www.amazon.com/shop/depyrol_____Podcast:https://i.

I'Ll Show You How To Make a Very Sturdy Sheet Metal Fabrication Enclosure That Is Easy To Build And Can Last For Decades. Why Should You Care About The Material You Use To Make Your Enclosures?You can make watertight trays from flat sheet metal without soldering or riviting. Take a sheet of metal whose length is the length of the finished tray plus two time the height of the sides;

sheet metal box steps

metal house price

metal house sign uk

Polish Manufacturer of metal and wood processing machinery. CORMAK offer is known worldwide for its high quality. Our stock includes only the finest devices, tested at each stage of manufacturing by our experienced technicians. We ensure the quality of our products and their compatibility with all CE norms.

best way to make a sheet metal box water proof|sheet metal box steps