cnc machine plant layout The major merits of a good plant layout are given as under: 1. Reduced men and machine hours per unit of production, 2. Effectively and economical utilization of entire floor space of the plant, . Standard metal roofing materials include copper, aluminum, steel, zinc, and tin, which come in varying shapes and sizes (slate, corrugated, tile). Metal roofing can last for decades, with many well-made metal roofs lasting anywhere from 50 to 80 years.

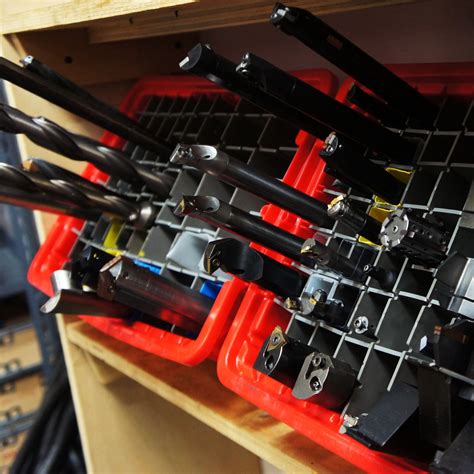

0 · how to organize cnc machines

1 · cnc tool shop floor layout

2 · cnc machine shop floor plan

3 · 3d cnc layout

4 · 3d cnc floor plan

Braces are orthodontic devices that straighten crooked and misaligned teeth with a system of metal brackets and wires. Dental braces are used for aesthetic and functional reasons, not only to correct a patient’s smile but also to realign their jaw.

In this comprehensive guide, we will delve into the key considerations and best practices for designing an efficient CNC machine shop floor layout that maximizes productivity and ensures .

Internal layout of the plant for CNC machine tools. [.] The characteristics of heat transfer load from the non-air-conditioned (NAC) area can help to understand the complex airflow. The small footprint of Okuma CNC machines can be quickly visualized by importing 3D models of the desired machine, and then you can make sure the machining . The time it takes to implement a CNC machine shop layout that naturally flows through each stage of the production process will be more than made up by the time you save, reducing the amount of ground that materials .The major merits of a good plant layout are given as under: 1. Reduced men and machine hours per unit of production, 2. Effectively and economical utilization of entire floor space of the plant, .

The facility layout is a well-planned process to assimilate equipment, human resources, and materials for processing a product most effectively. The facility layout problem .

how to organize cnc machines

cnc tool shop floor layout

This article utilises a scheme to solve both equal and unequal area department problems in facilities layout by using genetic algorithms (GAs) for achieving the minimal total . A well-planned machine shop layout is important for the efficiency, safety, and growth of your CNC business. By considering space requirements, electrical and ventilation needs, safety, ergonomics, storage, noise reduction, . Designing a machine-shop’s layout will directly impact efficiency and workflow, promoting contentment among the workers and increasing productivity, for more satisfied clientele. Find the best positions for each . A CNC machine shop’s layout can make a big difference. Find out the best ways to organize your shop for maximum work flow right here. Learn more today!

In this comprehensive guide, we will delve into the key considerations and best practices for designing an efficient CNC machine shop floor layout that maximizes productivity and ensures a smooth manufacturing process.Internal layout of the plant for CNC machine tools. [.] The characteristics of heat transfer load from the non-air-conditioned (NAC) area can help to understand the complex airflow. The small footprint of Okuma CNC machines can be quickly visualized by importing 3D models of the desired machine, and then you can make sure the machining center or CNC lathe will fit into your shop space. You can contact your distributor to obtain a 3D model of your Okuma machine.

The time it takes to implement a CNC machine shop layout that naturally flows through each stage of the production process will be more than made up by the time you save, reducing the amount of ground that materials and personnel must cover.The major merits of a good plant layout are given as under: 1. Reduced men and machine hours per unit of production, 2. Effectively and economical utilization of entire floor space of the plant, 3. Work flow is smooth and continuous 4. Work in process inventory is less 5. Production control is better 6. Manufacturing time is less 7.

cnc machine shop floor plan

The facility layout is a well-planned process to assimilate equipment, human resources, and materials for processing a product most effectively. The facility layout problem (FLP) is an optimization problem that involves determining the shape and location of various. This article utilises a scheme to solve both equal and unequal area department problems in facilities layout by using genetic algorithms (GAs) for achieving the minimal total layout cost.

A well-planned machine shop layout is important for the efficiency, safety, and growth of your CNC business. By considering space requirements, electrical and ventilation needs, safety, ergonomics, storage, noise reduction, and future expansion, you’re setting up your shop for success.

how to make a large flower box with corrugated metal

3d cnc layout

The selection, monitoring, and maintenance of CNC machining coolant are crucial for maintaining temperature control, chip evacuation, lubrication, and extending tool life. Read on to learn more about the different types of CNC machining coolants, their specific uses, and why they’re necessary to ensure precision in the machining process.

cnc machine plant layout|how to organize cnc machines