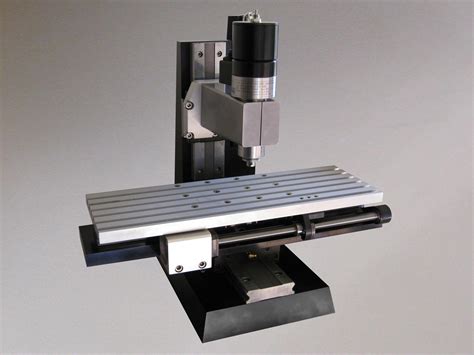

cheap homemade cnc milling machine In this video I'm going to show how I built a basic CNC mill. Most of the hardware was sourced from spare / leftover parts I had laying around from other projects and ended up . U-Bracket: As you might guess, these resemble the shape of a U. They are useful for mounting parallel surfaces together. The space between the two flanges is often used to retain a component, as it can hug both sides. U-brackets are often used to install things such as power supplies or hard-drives.

0 · make your own cnc mill

1 · make your own cnc machine

2 · home built cnc milling machine

3 · do it yourself cnc machine

4 · building your own cnc machine

5 · building my own cnc machine

6 · build your own milling machine

7 · build your own cnc mill

Learn more about the best metal roof features that meet your home’s needs and style. Each material available for your metal roof has unique features that set it apart from other choices. 1. Aluminum Roofing. Aluminum is one of the most popular types of metal roof materials, as it is durable and affordable.

Here is a way to make a computer controlled milling machine. That puts the real power of a computer control machining into the hands of the average human. Small enough to set on the .It should be possible to keep costs below 200 USD including everything from nuts, .In this Instructables, I’ll show you how I designed, fabricated, assembled, and .

Do your research on DIY CNC builds. You can find a lot here in instructables ( . In this video I'm going to show how I built a basic CNC mill. Most of the hardware was sourced from spare / leftover parts I had laying around from other projects and ended up .It should be possible to keep costs below 200 USD including everything from nuts, to cable sleeves and CNC controller. In this instructable I will do my best to explain how I made this . How to build a DIY CNC Milling machine from scratch that can cut aluminium and steel.My objective for this project was to design and build a CNC milling mach.

That is my best effort to give you everything I learn during the built of my cheap, DIY CNC. I linked all the drawings, that I made for it, in the descriptio. Budget: A DIY CNC machine can range from very affordable to quite expensive. Establish a budget beforehand to decide the extent and quality of components you can afford. Space: CNC machines, even DIY ones, can take . Commercial CNC machines cost thousands of dollars, but with effort you can build your own for much less. Thankfully, there are many well-documented hobby CNC projects on the internet to help us through this .Do your research on DIY CNC builds. You can find a lot here in instructables ( https://www.instructables.com/id/CNC/ ). Once you've decided on your design, doodle it.

Here is a way to make a computer controlled milling machine. That puts the real power of a computer control machining into the hands of the average human. Small enough to set on the desk but scalable to any size.In this video I'm going to show how I built a basic CNC mill. Most of the hardware was sourced from spare / leftover parts I had laying around from other projects and ended up costing me under.

It should be possible to keep costs below 200 USD including everything from nuts, to cable sleeves and CNC controller. In this instructable I will do my best to explain how I made this machine, so that you can do one on your own! Detailed bill of materials, files for 3D printing and drawings are available in this instructable. How to build a DIY CNC Milling machine from scratch that can cut aluminium and steel.My objective for this project was to design and build a CNC milling mach.In this Instructables, I’ll show you how I designed, fabricated, assembled, and got running this mini CNC milling machine. I love fabricating and I wanted to make a (relatively) low cost CNC mill to have at home during the pandemic.

That is my best effort to give you everything I learn during the built of my cheap, DIY CNC. I linked all the drawings, that I made for it, in the descriptio. Budget: A DIY CNC machine can range from very affordable to quite expensive. Establish a budget beforehand to decide the extent and quality of components you can afford. Space: CNC machines, even DIY ones, can take up a considerable amount of space. Ensure you have a dedicated workspace, preferably away from dust and moisture. Commercial CNC machines cost thousands of dollars, but with effort you can build your own for much less. Thankfully, there are many well-documented hobby CNC projects on the internet to help us through this process. A great source of inspiration for me was "Tom's Easy to build Desktop CNC Mill:"

Do your research on DIY CNC builds. You can find a lot here in instructables ( https://www.instructables.com/id/CNC/ ). Once you've decided on your design, doodle it.

Looking to buy a sturdy (aluminium ready) CNC mill. 6 inches in x and y axis would be enough for me. budget is around 00.Here is a way to make a computer controlled milling machine. That puts the real power of a computer control machining into the hands of the average human. Small enough to set on the desk but scalable to any size.

In this video I'm going to show how I built a basic CNC mill. Most of the hardware was sourced from spare / leftover parts I had laying around from other projects and ended up costing me under.

It should be possible to keep costs below 200 USD including everything from nuts, to cable sleeves and CNC controller. In this instructable I will do my best to explain how I made this machine, so that you can do one on your own! Detailed bill of materials, files for 3D printing and drawings are available in this instructable. How to build a DIY CNC Milling machine from scratch that can cut aluminium and steel.My objective for this project was to design and build a CNC milling mach.In this Instructables, I’ll show you how I designed, fabricated, assembled, and got running this mini CNC milling machine. I love fabricating and I wanted to make a (relatively) low cost CNC mill to have at home during the pandemic.

readily accessible junction box

That is my best effort to give you everything I learn during the built of my cheap, DIY CNC. I linked all the drawings, that I made for it, in the descriptio. Budget: A DIY CNC machine can range from very affordable to quite expensive. Establish a budget beforehand to decide the extent and quality of components you can afford. Space: CNC machines, even DIY ones, can take up a considerable amount of space. Ensure you have a dedicated workspace, preferably away from dust and moisture. Commercial CNC machines cost thousands of dollars, but with effort you can build your own for much less. Thankfully, there are many well-documented hobby CNC projects on the internet to help us through this process. A great source of inspiration for me was "Tom's Easy to build Desktop CNC Mill:"

Do your research on DIY CNC builds. You can find a lot here in instructables ( https://www.instructables.com/id/CNC/ ). Once you've decided on your design, doodle it.

make your own cnc mill

make your own cnc machine

Mini Center Compact is a reliable range of distribution boards allowing maximum flexibility, offering wide choice of incomers: Switch Disconnector, MCCB, MCB, RCCB, RCD or direct cable connection. The busbar design eliminates risk of the hot spots. Busbar and terminals are shrouded for additional safety protection.

cheap homemade cnc milling machine|make your own cnc mill