basics of sheet metal fabrication This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting. Drivers in Richmond have paid more than two million pounds in fines at yellow box junctions in the borough since 2016. At the junction between Castelnau with Trinity Church Road almost 7,000 penalty charge notices were issued in 2018, raking in nearly half a .

0 · working with sheet metal basics

1 · types of sheet metal fabrication

2 · sheet metal part design guidelines

3 · sheet metal manufacturing process types

4 · sheet metal fabrication standards

5 · sheet metal fabrication capabilities

6 · design for manufacturing sheet metal

7 · design considerations for sheet metal

Browse 7,219 STEEL FABRICATION jobs ($62k-$105k) from companies with openings that are hiring now. Find job postings near you and 1-click apply!

Learn what sheet metal fabrication is, how it works, and what materials and processes are involved. This guide covers cutting, bending, welding, and finishing methods for sheet metal parts.

This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: . This complete guide’ll walk you through the basics of sheet metal fabrication and provide all the information you need to get started. From understanding the materials and processes involved to tips on finding the right fabrication shop for .This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting. Sheet metal fabrication is an essential process for many industries, enabling the creation of complex and precise metal components. Understanding the various fabrication techniques is crucial for effective decision-making, cost optimization, and quality control.

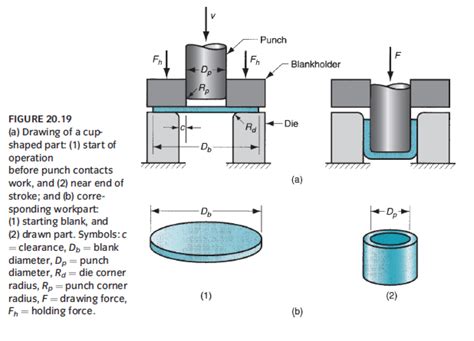

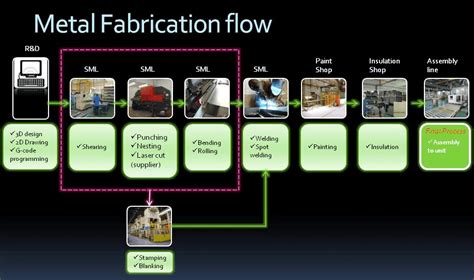

Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets into the final part. What Is Sheet Metal Fabrication? Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually comprises of many steps – from cutting and .

In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies.Sheet metal fabrication involves fabricating parts, components, and assemblies from metal sheets. It encompasses many operations, such as shearing, blanking, bending, welding, riveting, mold forming, and surface treatment.

Explore the comprehensive guide to sheet metal fabrication with Shengen, the B2B manufacturer. Uncover techniques, trends, and applications.

Sheet metal fabrication is the process of transforming sheet metal (< 1/4” thick) into finished products, structures, and components. From household appliances to transportation, commercial equipment to construction, sheet metal fabrication is critical to modern manufacturing. In this article, we will cover the basics of sheet metal fabrication. We aim to shed light on this metal production technique with numerous applications across many industries. This complete guide’ll walk you through the basics of sheet metal fabrication and provide all the information you need to get started. From understanding the materials and processes involved to tips on finding the right fabrication shop for .

This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting. Sheet metal fabrication is an essential process for many industries, enabling the creation of complex and precise metal components. Understanding the various fabrication techniques is crucial for effective decision-making, cost optimization, and quality control.Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets into the final part. What Is Sheet Metal Fabrication? Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually comprises of many steps – from cutting and .

In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies.Sheet metal fabrication involves fabricating parts, components, and assemblies from metal sheets. It encompasses many operations, such as shearing, blanking, bending, welding, riveting, mold forming, and surface treatment.Explore the comprehensive guide to sheet metal fabrication with Shengen, the B2B manufacturer. Uncover techniques, trends, and applications. Sheet metal fabrication is the process of transforming sheet metal (< 1/4” thick) into finished products, structures, and components. From household appliances to transportation, commercial equipment to construction, sheet metal fabrication is critical to modern manufacturing.

working with sheet metal basics

powder metal laser cut custom mail box name

Just reading in the paper this morning about how a council raking in nearly £70,000 in fines in just a month form a camera at a yellow box junction. Now I'm not at all in favour of cameras put in places purely to make money, but one a .

basics of sheet metal fabrication|design considerations for sheet metal