bend allowance in sheet metal Calculate the bend allowance, bend deduction, and setback for a bent piece of sheet metal using the sheet thickness, bend radius, bend angle, and K-factor. Learn more about bending and the formulae used by this calculator. Stainless steel appliances stand out when paired with the right color cabinets because it sets the tone for a modern, sleek, and stylish kitchen aesthetic. White cabinets are versatile, market-friendly, and easy to maintain. Gray cabinets offer versatility, balance, and monochromatic appeal.

0 · sheet metal bend deduction chart

1 · sheet metal bend calculation formula

2 · sheet metal bend allowance formula

3 · sheet metal bend allowance chart

4 · how to find bend allowance

5 · how to calculate bend deduction sheet metal

6 · bend allowance chart pdf

7 · bend allowance calculator for sheet metal

I would really appreciate it if I could get some input from you guys on what machine you think would be appropriate for the job, as well as what end mills you recommend. After doing some research the machine + tools I think are sufficient: CNC Machine - Genmitsu 3020-Pro Max V2 (or Genmitsu 4030 V2 if needed)This introductory article explains the main types of CNC machines, from CNC routers and milling machines, to less common types like Oxy-Fuel machines.

sheet metal bend deduction chart

cnc precision turned parts company

sheet metal bend calculation formula

With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too! Bend allowance is a fundamental tool for mold designers in the sheet metal industry. It allows for precise calculation of the unfold dimensions of press-bent parts, ensuring that the final product meets the design .Calculate the bend allowance, bend deduction, and setback for a bent piece of sheet metal using the sheet thickness, bend radius, bend angle, and K-factor. Learn more about bending and the formulae used by this calculator.

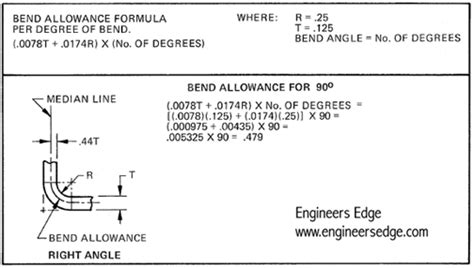

Bend allowance is the distance between the points where the metal is bent. This measurement determines how much material needs to be removed in order to create a . Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a .The following illustration shows the equation / calculation for determining the bend allowance when forming sheet metal. Most sheet metal materials will conform to the calculations. This page also includes a link to a on-line sheet metal bend .

Bend compensation is essential to ensure the metal sheet achieves the desired dimensions and shape after bending. Join me as we explore the intricacies of bend allowance. Understanding this concept will elevate your metalworking . Use SendCutSend’s bending calculator to input your desired material and the units of measurement for your design to get the calculated bend allowance and bend deduction for your part before sending it to our lasers. .

cnc precision machining comstock park mi

Learn what is sheet metal bend allowance and how to calculate it using a formula and a calculator. Find out how to use bend allowance to create a flat pattern for a bent component. The bend allowance chart is an essential resource for professionals working with sheet metal fabrication. It provides a comprehensive listing of key parameters such as material thickness, bending radius, bending angle, bend allowance, and bend deduction values for common materials. With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too! Bend allowance is a fundamental tool for mold designers in the sheet metal industry. It allows for precise calculation of the unfold dimensions of press-bent parts, ensuring that the final product meets the design specifications and quality standards.

Calculate the bend allowance, bend deduction, and setback for a bent piece of sheet metal, or use this information to determine the K-factor. Bend allowance is the distance between the points where the metal is bent. This measurement determines how much material needs to be removed in order to create a smooth, finished product. This sheet metal bend radius calculator can help you quickly and easily determine your project's bend allowance. Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at .

The following illustration shows the equation / calculation for determining the bend allowance when forming sheet metal. Most sheet metal materials will conform to the calculations. This page also includes a link to a on-line sheet metal bend allowance calculator.

Bend compensation is essential to ensure the metal sheet achieves the desired dimensions and shape after bending. Join me as we explore the intricacies of bend allowance. Understanding this concept will elevate your metalworking skills, whether you’re a DIY enthusiast or a professional.

Use SendCutSend’s bending calculator to input your desired material and the units of measurement for your design to get the calculated bend allowance and bend deduction for your part before sending it to our lasers. The calculator also allows you to input flanges. Select material type, thickness, and desired units. Enter your base length.

Sheet Metal Bend Allowance. When a piece of sheet metal goes through the process of bending, its upper layer (with inside radius) is compressed and the lower layer (with outside radius) is stretched. Due to this tension and compression, the length of the sheet metal piece increases.

The bend allowance chart is an essential resource for professionals working with sheet metal fabrication. It provides a comprehensive listing of key parameters such as material thickness, bending radius, bending angle, bend allowance, and bend deduction values for common materials. With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too! Bend allowance is a fundamental tool for mold designers in the sheet metal industry. It allows for precise calculation of the unfold dimensions of press-bent parts, ensuring that the final product meets the design specifications and quality standards.Calculate the bend allowance, bend deduction, and setback for a bent piece of sheet metal, or use this information to determine the K-factor.

Bend allowance is the distance between the points where the metal is bent. This measurement determines how much material needs to be removed in order to create a smooth, finished product. This sheet metal bend radius calculator can help you quickly and easily determine your project's bend allowance.

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at .The following illustration shows the equation / calculation for determining the bend allowance when forming sheet metal. Most sheet metal materials will conform to the calculations. This page also includes a link to a on-line sheet metal bend allowance calculator.Bend compensation is essential to ensure the metal sheet achieves the desired dimensions and shape after bending. Join me as we explore the intricacies of bend allowance. Understanding this concept will elevate your metalworking skills, whether you’re a DIY enthusiast or a professional.

Use SendCutSend’s bending calculator to input your desired material and the units of measurement for your design to get the calculated bend allowance and bend deduction for your part before sending it to our lasers. The calculator also allows you to input flanges. Select material type, thickness, and desired units. Enter your base length.

Whites, beiges, and tans tend to be the most energy-efficient roof colors. If you live in a warm climate, avoid dark-colored roofing. Metal roofing and cedar shakes are some of the most energy-efficient materials. You may not .

bend allowance in sheet metal|how to find bend allowance