how to connect sheet metal together No welding equipment? No problem! Today we show the #verycoolgang 3 different ways to attach two pieces of metal without using a welder! TRINITY PRO 72" Stainless Steel Rolling Workbench with Adjustable-Height Top Solid 1.5” Thick Butcher Block Top; Top Adjustable Height 0” - 12” Ball Bearing Drawer Slides; Total Weight Capacity 2,200 Lbs

0 · sheet metal joining technology

1 · sheet metal joining techniques

2 · sheet metal joining screws

3 · sheet metal joining process

4 · sheet metal connection process

5 · how to join sheet metal

6 · best way to join metal

7 · attaching metal to steel without welding

Starfield USB/SD holder. Discover 3D models for 3D printing related to Usb Holder. Download your favorite STL files and make them with your 3D printer. Have a good time!

No welding equipment? No problem! Today we show the #verycoolgang 3 different ways to attach two pieces of metal without using a welder!

How can we ensure secure and durable connections in sheet metal fabrication? This article explores various joining and fastening techniques, including TOX riveting, welding, and nail riveting. You’ll discover the pros and .

Metal sheets can be joined using snap-fits, which use spring force to hold parts together. This includes spring clips that provide a fast option for sheet metal joins by holding them together under sprung force, as well as permanent and non .

The simplest method is acting like a regular standoff with threads to stack two parts on top of each other. The other way to use standoffs similar to PEM Nuts. Industrial adhesive, like epoxy, creates a strong, permanent bond between the metals, while mechanical fasteners, like bolts and screws, securely hold the pieces together. Before bonding, clean and rough up the metal .© 2024 Google LLC. One of my favorite ways to join metal! Pop rivets are easy to install but can be tricky to get holes to line up. There are thousands of different styles of .For my boat I need to manufacture a mast entry gate, as they don't sell any in the size I need and local metal workshops just refuse to take the work (probably because it's a small job and they can't be arsed, but who knows really). Either way. I will need 3 sheets of metal, very thin, on top of each other and need to hold them together somehow.

Connecting rectangular ductwork may not be obvious at first glance. But once you know the pieces, the job to connect rectangular ductwork is really pretty si. Metal sections that are 0.5 inch or thicker can be handled with almost equal efficiency by both methods. Thinner sections are better joined by brazing. Here is an example. You want to adopt brazing when you’re working to create a T-joint bonding a piece of sheet metal to metal stock where the thickness of both pieces is 0.5 inch.

Follow along as I show you 4 different ways to join sheet metal! We'll introduce hand seaming, pop rivets, soft iron rivets, and spot welding. While we are. One of my favorite ways to join metal! Pop rivets are easy to install but can be tricky to get holes to line up. There are thousands of different styles of . It’s primarily useful for joining lightweight metal pieces together. Cons. Leaks can cause gaps in joints, which are not impervious to leaks. Welding Fundamentals. Welding is the process of joining two metal pieces together to form a strong bond. During this procedure, you can add a filler or a flux while applying heat.

Shows you how to connect square ductwork. Good information when installing your return air.Amazon link to Great products that every DIYer and Handyman should.How To Connect Sheet Metal Together. From www.vandf.co.uk. How to connect metal without welding, sheet metal joining methods How To Connect Sheet Metal Together But if you’ve got thin metal sheeting you want to connect, riveting or screwing them together is the way to go. one of the most common methods of joining two pieces of metals together . Are you looking to switch away from welding?You’re struggling to find highly skilled welders or you are experiencing issues with welded joints?Here at Forgew. Super Alloy 1 contains cadmium. Super Alloy 1 can easily solder galvanized steel plates together. Super Alloy 1 has a very low melting point which prevents t.

electrical box opening is smaller than box

I have been doing some basic HVAC duct work as part of a remodeling project and I can never get the pieces to fit together without massive amounts of elbow grease and mangling the ends. Is there some kind of trick that I am missing that makes it easier? I am working with 6 inch, and 7 inch sheet metal duct and vent boots as well as some flex duct. How to use a rivet gun. in this video I show you how to join two pieces of metal together using a rivet gun. it is easy to do and very cost effective if you .

Here we show you how to adjust a round sheet metal duct elbow for 90°, 45°, 35° or from 0° to 90° or anything in between. It may seem confusing adjusting a r.

I'm creating a metal frame out of 2" square steel tubing (16ga). Then I want to attach a sheet of 16ga sheet metal to the back (no welding). I'm going to fill the inside of the frame with wood to make a door.

electrical box not allowing electrical fuse rust

Rigid square duct uses slips and drives to hold it together, google it. The circular duct is fine with just a few pieces of HVAC tape around it. Some people throw a couple HVAC sheet metal screws through the joint for more strength, but it but this acts as . The overall goal is to take 2 parts and make them into a sheet metal part. I converted one part into a sheet metal one and then copied the sketch from the other part. Sketch 6 is the other part and I pasted it into the sheet metal part. I want to make a face out of this sketch and then fold the part along a construction line. I want to create the funnel by connecting 4 separate sides with flanges. In the attached file, I created a funnel for a hopper using the lofted flange feature. I then ripped the corners. After that I created overlapping corner seams and then attempted to ad flanges. Two of the four flanges have errors -- they contact the other side of the funnel. Is there a way . A great video that will show you how east it can be to put together round duct work. This can be difficult at times but with some practice these pieces of du.

In this video we demonstrate how to join downpipes together.--Perth Wide Custom Steel Shed Suppliers and Builderssite: https://royssheds.com.au/Phone: 08 .Question on joining metal together without welding. I need to make an aluminum frame for the top and bottom of an aquarium, using 1.25x1.25 angle stock. I do not have the place or tools for welding this so I plan to connect the corner with L-brackets (cut from 3x3 angle to a length of 1.25” creating a custom L). Ep 16 - Our presenter Katherine Grocott demonstrates how to join metal using rivets. All tools available from https://www.jewellerssupplies.com.au SOLIDWORKS Sheet Metal Tutorial (Full Course 2hr:05min) playListhttps://www.youtube.com/playlist?list=PLx-VY2mDlK2H6eywmlpdQf2-Xpm_NqQxQvideo-tutorials.net

sheet metal joining technology

In this video I’ll show you how to glue metal to metal using epoxy adhesive and alcohol.SUBSCRIBE! https://goo.gl/hI8FqH-----. How To Put Together Round Duct Work. Snap Lock Pipe Assembly. Assemble, Cut & Connect Snap Lock Ducting Correctly!HOW TO INSTALL KITCHEN RANGE HOOD: https://.

How to easily bolt into metal tubes, steel sheets, trailers, and much more with ease by using this fantastic time saving rivet nut tool. Enjoy the video! Riv.In this HVAC Training Video, I show 3 Ways to Connect and Hang Ductwork. This is a Sheet Metal Basics Video for New Techs, Apprentices, and Helpers. Supervis. Assemble the metal ducting like a zipper. When assembling pipe, start at one end and work the seam together like a zipper. Use one hand to keep the two edges close and the other to apply downward pressure. Use your leg, a workbench or the ground to support the back side of the pipe.

sheet metal joining techniques

electrical box on drain line

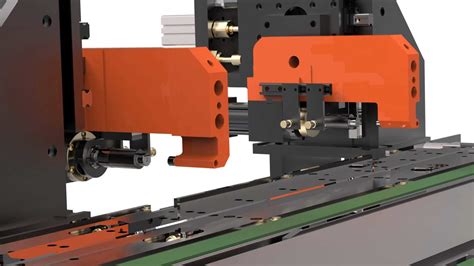

This guide thoroughly explores precision machined parts, their importance, and different machine tools used to create custom precision parts. Read on to the end to learn the materials used for precision machined parts, industry applications, and advancement in tooling for precision machining.

how to connect sheet metal together|sheet metal joining screws