a cnc milling machine would have In a nutshell, a CNC milling machine is a cutting-edge piece of equipment that uses programmed instructions to automate the cutting, drilling, and shaping of materials.. Unlike manual milling, . There are many ways to cut sheet metal, which one you need to use depends on the project. The following is a primer of tools and techniques for cutting sheet metal. The most important factor to consider when working with .

0 · types of cnc milling machines

1 · most affordable cnc milling machines

2 · cnc milling machine pdf

3 · cnc milling machine near me

4 · cnc milling machine description

5 · cnc milling machine definition

6 · best milling machine for small shop

7 · affordable cnc milling machines

The switchgear arrangement on each distribution side is housed in metal-enclosed structures called as LT (low tension) panels. These LT panels are responsible for distributing the power to various sub LT panels by receiving it from the transformer.

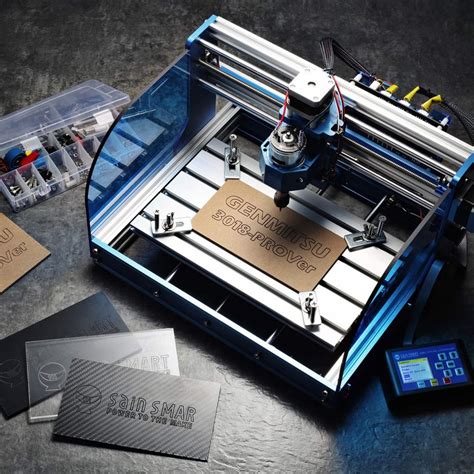

This guide covers milling machines A-Z, including types, uses, and features so you can make an informed decision when choosing your next milling machine. A CNC milling machine is a sophisticated piece of equipment that automates the process of cutting and shaping materials, such as metal, plastic, or wood. Standing for Computer Numerical Control, CNC milling leverages .

In a nutshell, a CNC milling machine is a cutting-edge piece of equipment that uses programmed instructions to automate the cutting, drilling, and shaping of materials.. Unlike manual milling, .CNC milling is a subtractive manufacturing process in which a computer-controlled rotating cutting tool selectively removes portions of a block of material to form a desired object. Milling technology existed as a manufacturing . CNC milling is a subtractive manufacturing process that combines traditional milling with computer numerical control (CNC) technology. It involves using a rotating cutting tool to remove material from a solid block of metal, plastic, wood, or other materials to create precise parts and products.

This guide covers milling machines A-Z, including types, uses, and features so you can make an informed decision when choosing your next milling machine. A CNC milling machine is a sophisticated piece of equipment that automates the process of cutting and shaping materials, such as metal, plastic, or wood. Standing for Computer Numerical Control, CNC milling leverages computerized systems to control the movement and operation of the cutting tools with extreme precision.In a nutshell, a CNC milling machine is a cutting-edge piece of equipment that uses programmed instructions to automate the cutting, drilling, and shaping of materials.. Unlike manual milling, where an operator’s steady hand (or lack thereof) makes all the difference, CNC milling brings a super-high level of consistency that manual methods could only dream of.CNC milling is a subtractive manufacturing process in which a computer-controlled rotating cutting tool selectively removes portions of a block of material to form a desired object. Milling technology existed as a manufacturing process before the incorporation of CNC .

Milling machines are the most common CNC equipment. They use a multi-point rotating cutting tool attached to a CNC-controlled spindle. Consequently, the spindle can move across multiple axes (3, 5, or more) to remove the material. CNC milling machine is usually composed of shaft, worktable, spindle, frame, CNC controller, coolant, lubrication system, power tie rod, housing, axis, etc. How Does a CNC Milling Machine Work? Before running the CNC program, secure the workpiece to the worktable of the CNC milling machine, and mount the cutting tools on the spindle.

CNC milling is a subtractive manufacturing process that uses computer-controlled, multi-point, rotary cutters to remove material from a workpiece and produce a custom-designed part or product. The process begins with a 3D CAD model converted into a .CNC milling is the most common form of CNC process and was the first type used with CNC machines in 1952. Milling is one of the oldest manufacturing processes that began in the early part of the 19th Century.CNC milling machines are among the most versatile and widely used in the industry. They operate by rotating a cutting tool against a stationary workpiece, allowing for intricate shapes and designs to be crafted with high precision.

CNC milling is a subtractive manufacturing process that combines traditional milling with computer numerical control (CNC) technology. It involves using a rotating cutting tool to remove material from a solid block of metal, plastic, wood, or other materials to create precise parts and products. This guide covers milling machines A-Z, including types, uses, and features so you can make an informed decision when choosing your next milling machine.

A CNC milling machine is a sophisticated piece of equipment that automates the process of cutting and shaping materials, such as metal, plastic, or wood. Standing for Computer Numerical Control, CNC milling leverages computerized systems to control the movement and operation of the cutting tools with extreme precision.In a nutshell, a CNC milling machine is a cutting-edge piece of equipment that uses programmed instructions to automate the cutting, drilling, and shaping of materials.. Unlike manual milling, where an operator’s steady hand (or lack thereof) makes all the difference, CNC milling brings a super-high level of consistency that manual methods could only dream of.CNC milling is a subtractive manufacturing process in which a computer-controlled rotating cutting tool selectively removes portions of a block of material to form a desired object. Milling technology existed as a manufacturing process before the incorporation of CNC .

types of cnc milling machines

Milling machines are the most common CNC equipment. They use a multi-point rotating cutting tool attached to a CNC-controlled spindle. Consequently, the spindle can move across multiple axes (3, 5, or more) to remove the material. CNC milling machine is usually composed of shaft, worktable, spindle, frame, CNC controller, coolant, lubrication system, power tie rod, housing, axis, etc. How Does a CNC Milling Machine Work? Before running the CNC program, secure the workpiece to the worktable of the CNC milling machine, and mount the cutting tools on the spindle.

metal fabricators glasgow

CNC milling is a subtractive manufacturing process that uses computer-controlled, multi-point, rotary cutters to remove material from a workpiece and produce a custom-designed part or product. The process begins with a 3D CAD model converted into a .CNC milling is the most common form of CNC process and was the first type used with CNC machines in 1952. Milling is one of the oldest manufacturing processes that began in the early part of the 19th Century.

most affordable cnc milling machines

cnc milling machine pdf

What is Sheet Metal Processing? "Sheet metal" in sheet metal processing refers to thin metal plates, which can be processed by stretching, stamping, bending, etc., and the thickness is usually less than 6mm.

a cnc milling machine would have|most affordable cnc milling machines