box of metal layout Learn the basics of sheet metal layout including different seams, techniques and tricks. This video also includes the patterns and layout methods for creati. The WAGOBOX ® Light junction box is for use with our 224, 260 and 294 Series connectors. WAGOBOX ® LIGHT Suitable for lighting applications using WAGO's 224 series.

0 · sheet metal box patterns

1 · sheet metal box layout

2 · sheet metal box instructions pdf

3 · sheet metal box dimensions

4 · sheet metal box design template

5 · how to make sheet metal boxes

6 · how to make a metal box

7 · how to fabricate sheet metal box

VTS Sheet Metal Specialists, metal fabricator, listed under "Metal Fabricators" category, is located at 1041 N Grove St Anaheim CA, 92806 and can be reached by 7142371420 phone number. .

In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my . Learn the basics of sheet metal layout including different seams, techniques and tricks. This video also includes the patterns and layout methods for creati. To fabricate a sheet metal box, you will need a sheet metal of your desired thickness, a metal shear or snips, a metal brake, a drill press or hand drill, a deburring tool, a tape measure, a square, and safety equipment such as .A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on. We're not going to touch upon bend .

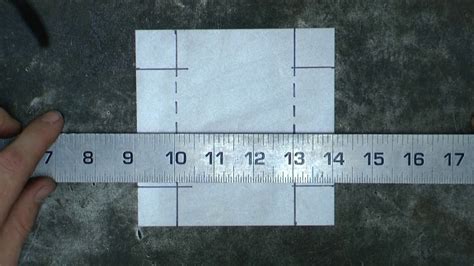

How to Make a Sheet Metal Box: 1) first you want to make an expanded template for your box out of cardboard, paper, etc. ( a flat version of your box. I have a .

Creating sheet metal boxes involves a series of precise steps that ensure the final product is both functional and aesthetically pleasing. This guide will take you through the . Designing an effective sheet metal enclosure requires a little bit of planning and few considerations. By following these tips you can both design and build quality enclosures from sheet metal. If sheet metal fabrication is outside . Designing a sheet metal box involves several steps to ensure it meets functional and aesthetic requirements. Here’s a general guide to get you started: 1. Define Requirements. Dimensions: Length, width, and height. .

Fabricating a sheet metal box involves transforming a flat sheet of metal into a three-dimensional structure with sides and a bottom. This process requires precision, careful planning, and the use of various techniques.

A box can be formed the same way as the U-channel described on in the previous paragraphs, but when a sheet metal part has intersecting bend radii, it is necessary to remove material to make room for the material contained in the .In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my two previous sheet metal Instructables. They cover how to make SHEET METAL DOG TAGS and SHEET METAL VISE JAW COVERS. Learn the basics of sheet metal layout including different seams, techniques and tricks. This video also includes the patterns and layout methods for creati. To fabricate a sheet metal box, you will need a sheet metal of your desired thickness, a metal shear or snips, a metal brake, a drill press or hand drill, a deburring tool, a tape measure, a square, and safety equipment such as safety glasses and gloves.

A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on. We're not going to touch upon bend radii or bend allowances, but these.How to Make a Sheet Metal Box: 1) first you want to make an expanded template for your box out of cardboard, paper, etc. ( a flat version of your box. I have a graph paper drawing in the pics below, but its not for this box) 2) trace your template on to your piece of sheet m. Creating sheet metal boxes involves a series of precise steps that ensure the final product is both functional and aesthetically pleasing. This guide will take you through the process of designing, cutting, and folding sheet metal to create durable and well-fitted boxes. Designing an effective sheet metal enclosure requires a little bit of planning and few considerations. By following these tips you can both design and build quality enclosures from sheet metal. If sheet metal fabrication is outside your current skill set or you don’t have the time or desire, SendCutSend can assist with most of the fabrication.

Designing a sheet metal box involves several steps to ensure it meets functional and aesthetic requirements. Here’s a general guide to get you started: 1. Define Requirements. Dimensions: Length, width, and height. Material: Type of sheet metal (e.g., aluminum, stainless steel, galvanized steel). Thickness: Gauge of the sheet metal.

sheet metal box patterns

sheet metal box layout

Fabricating a sheet metal box involves transforming a flat sheet of metal into a three-dimensional structure with sides and a bottom. This process requires precision, careful planning, and the use of various techniques.

A box can be formed the same way as the U-channel described on in the previous paragraphs, but when a sheet metal part has intersecting bend radii, it is necessary to remove material to make room for the material contained in the flanges. This is done by drilling or punching holes at the intersection of the inside bend tangent lines.

In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my two previous sheet metal Instructables. They cover how to make SHEET METAL DOG TAGS and SHEET METAL VISE JAW COVERS.

Learn the basics of sheet metal layout including different seams, techniques and tricks. This video also includes the patterns and layout methods for creati.

To fabricate a sheet metal box, you will need a sheet metal of your desired thickness, a metal shear or snips, a metal brake, a drill press or hand drill, a deburring tool, a tape measure, a square, and safety equipment such as safety glasses and gloves.A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on. We're not going to touch upon bend radii or bend allowances, but these.How to Make a Sheet Metal Box: 1) first you want to make an expanded template for your box out of cardboard, paper, etc. ( a flat version of your box. I have a graph paper drawing in the pics below, but its not for this box) 2) trace your template on to your piece of sheet m. Creating sheet metal boxes involves a series of precise steps that ensure the final product is both functional and aesthetically pleasing. This guide will take you through the process of designing, cutting, and folding sheet metal to create durable and well-fitted boxes.

Designing an effective sheet metal enclosure requires a little bit of planning and few considerations. By following these tips you can both design and build quality enclosures from sheet metal. If sheet metal fabrication is outside your current skill set or you don’t have the time or desire, SendCutSend can assist with most of the fabrication. Designing a sheet metal box involves several steps to ensure it meets functional and aesthetic requirements. Here’s a general guide to get you started: 1. Define Requirements. Dimensions: Length, width, and height. Material: Type of sheet metal (e.g., aluminum, stainless steel, galvanized steel). Thickness: Gauge of the sheet metal.

Fabricating a sheet metal box involves transforming a flat sheet of metal into a three-dimensional structure with sides and a bottom. This process requires precision, careful planning, and the use of various techniques.

sheet metal box instructions pdf

sheet metal box dimensions

Walkerflex is a modular in-floor power distribution system featuring standardized cable, connectors and prewired junction boxes that allow for faster on-site deployment of power. The system is designed to be used in raised floor applications and open ceiling concepts.

box of metal layout|sheet metal box design template