electrical junction box clearance requirements Many places definitely consider switchboards and panelboards to fall into that classification, but if you have a junction box and want to take voltage or current measurements in it - that sort of fits into that description, yet those area almost never required to comply with . Shoot the junction box on the floor above it with the Electric to unlock it. While it turns out to be a dead end, you can look for similar scrapes to find something more. On the second floor, to the right of the entrance (facing the doors), is another door.

0 · sizing junction boxes per nec

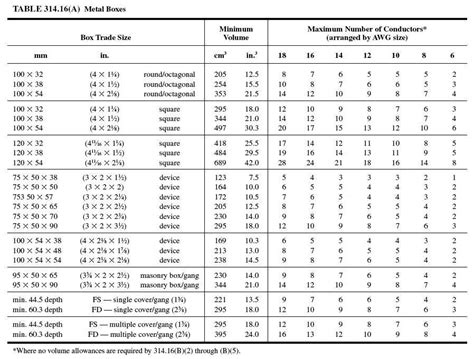

1 · nec junction box size chart

2 · maximum distance between junction boxes

3 · junction box sizing chart

4 · junction box accessibility code requirements

5 · electrical junction box wiring diagram

6 · electrical box sizing chart

7 · calculating junction box size nec

$35.99

sizing junction boxes per nec

Many places definitely consider switchboards and panelboards to fall into that classification, but if you have a junction box and want to take voltage or current measurements in it - that sort of fits into that description, yet those area almost never required to comply with .

Unused openings in boxes, raceways, auxiliary gutters, cabinets, equipment cases, or housings shall be effectively closed to afford protection substantially equivalent to the wall of the .For equipment designed for floor mounting, clearance between top surfaces and adjacent surfaces shall be provided to dissipate rising warm air. Electrical equipment provided with .In addition to other requirements in this section, the following requirements apply to pull and junction boxes for systems over 600 volts, nominal: 1910.305(b)(3)(i) Boxes shall provide a .

radiator metal grill sheets

nec junction box size chart

The rules for pull boxes, junction boxes, and outlet boxes cover five areas. In summary: Minimum size [314.28(A)]. These requirements constitute most of Sec. 314.28. One key point is that on straight pulls the box or conduit .

The working clearance space includes the zone described in Sec. 110.26(A). Architectural appurtenances or other equipment are not permitted within this zone. Rooms or enclosures containing electrical equipment . A good example is a junction box installed in an attic with no working space or clearance space required by 110.26 (A) for proper installation. This installation is acceptable . You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and . Many places definitely consider switchboards and panelboards to fall into that classification, but if you have a junction box and want to take voltage or current measurements in it - that sort of fits into that description, yet those area almost never required to .

Unused openings in boxes, raceways, auxiliary gutters, cabinets, equipment cases, or housings shall be effectively closed to afford protection substantially equivalent to the wall of the equipment.

Section 110.26 specifies the requirements for the clearance area around electrical equipment, including junction boxes. Section 110.26(A) requires a clear space of at least 30 inches wide by 36 inches deep.For equipment designed for floor mounting, clearance between top surfaces and adjacent surfaces shall be provided to dissipate rising warm air. Electrical equipment provided with ventilating openings shall be installed so that walls or other obstructions do not prevent the free circulation of air through the equipment.In addition to other requirements in this section, the following requirements apply to pull and junction boxes for systems over 600 volts, nominal: 1910.305(b)(3)(i) Boxes shall provide a complete enclosure for the contained conductors or cables.

The rules for pull boxes, junction boxes, and outlet boxes cover five areas. In summary: Minimum size [314.28(A)]. These requirements constitute most of Sec. 314.28. One key point is that on straight pulls the box or conduit body length must be at least eight times the trade size of the raceway. The working clearance space includes the zone described in Sec. 110.26(A). Architectural appurtenances or other equipment are not permitted within this zone. Rooms or enclosures containing electrical equipment controlled by a lock are considered accessible to qualified persons [Sec. 110.26(F)]. A good example is a junction box installed in an attic with no working space or clearance space required by 110.26 (A) for proper installation. This installation is acceptable because there are no exposed live parts to be worked on while energized.

raco electrical box catalog

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.

There is not a standard electrical code requirement that gives the minimum clearance distance between an electrical panel and a plumbing fixture, but you can figure a minimum distance from plumbing to panel by at least following the working space requirements.

Many places definitely consider switchboards and panelboards to fall into that classification, but if you have a junction box and want to take voltage or current measurements in it - that sort of fits into that description, yet those area almost never required to .

Unused openings in boxes, raceways, auxiliary gutters, cabinets, equipment cases, or housings shall be effectively closed to afford protection substantially equivalent to the wall of the equipment. Section 110.26 specifies the requirements for the clearance area around electrical equipment, including junction boxes. Section 110.26(A) requires a clear space of at least 30 inches wide by 36 inches deep.For equipment designed for floor mounting, clearance between top surfaces and adjacent surfaces shall be provided to dissipate rising warm air. Electrical equipment provided with ventilating openings shall be installed so that walls or other obstructions do not prevent the free circulation of air through the equipment.In addition to other requirements in this section, the following requirements apply to pull and junction boxes for systems over 600 volts, nominal: 1910.305(b)(3)(i) Boxes shall provide a complete enclosure for the contained conductors or cables.

The rules for pull boxes, junction boxes, and outlet boxes cover five areas. In summary: Minimum size [314.28(A)]. These requirements constitute most of Sec. 314.28. One key point is that on straight pulls the box or conduit body length must be at least eight times the trade size of the raceway. The working clearance space includes the zone described in Sec. 110.26(A). Architectural appurtenances or other equipment are not permitted within this zone. Rooms or enclosures containing electrical equipment controlled by a lock are considered accessible to qualified persons [Sec. 110.26(F)].

A good example is a junction box installed in an attic with no working space or clearance space required by 110.26 (A) for proper installation. This installation is acceptable because there are no exposed live parts to be worked on while energized. You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.

maximum distance between junction boxes

Open your scanner (press F on keyboard) to get the direction to the junction box. Jump across the broken platform to reach the panel shown in the image above. Open the panel door and activate the Junction Box 36B. Now, the location of two other Junction Boxes will appear on your screen.It sounds like you've done thorough troubleshooting, from checking the alternator's charging voltage to identifying a parasitic draw associated with the HVAC/ECAS fuse circuit. The fact that removing the Climate Control Module .

electrical junction box clearance requirements|calculating junction box size nec