electrical enclosures design An electrical enclosure is a purpose-built cabinet designed to house electrical and electronic devices, providing the required protection to keep operators/personnel safe from electrical . 2.6.6 Optional Equipment Dispensers contain an extra pair of data wires in the junction box for Wayne TRAC as shown in Figure 2-6 below. These wires are also identified in the installation wiring diagram in Appendix B. Dispensers with the letter I in the model number will have an intercom call button.

0 · thermal insulation for electrical enclosures

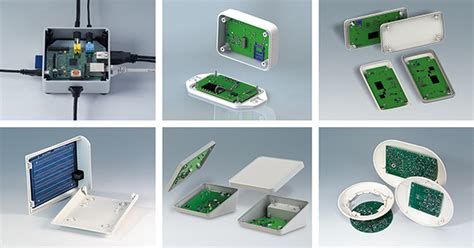

1 · pcb enclosure design guidelines

2 · inside of industrial electrical cabinet

3 · enclosure design of electronics equipment

4 · electronic enclosure design guidelines

5 · electrical enclosure types

6 · different types of wiring enclosures

7 · different types of electrical enclosures

$429.00

An electrical enclosure is a purpose-built cabinet designed to house electrical and electronic devices, providing the required protection to keep operators/personnel safe from electrical .Designing enclosures is a critical aspect of creating electronic devices, machines and systems. These systems or machines could be various testing & measuring equipment, medical devices, consumer electronics, diagnostic equipment and .An electrical enclosure is a purpose-built cabinet designed to house electrical and electronic devices, providing the required protection to keep operators/personnel safe from electrical shock hazards and devices protected from hazardous environments as well as accidentalDesigning enclosures is a critical aspect of creating electronic devices, machines and systems. These systems or machines could be various testing & measuring equipment, medical devices, consumer electronics, diagnostic equipment and so on.

Key steps to consider for main electrical enclosure design: component selection; enclosure type and size; component layout; safety and regulations. Key code areas in NEC and NFPA 79: general operating conditions; protection from electric shock; protection of equipment; grounding; conductors and cables; wiring practices; marking and safety signs . As a first step in designing an enclosure, you need to choose the type of metal you will use and its thickness. Protocase stocks all of the metals generally used to make enclosures, including aluminum, stainless steel, carbon steel (cold-rolled steel or galvanneal) and copper.

Electrical enclosure design includes all the steps involved in creating housing for electrical components. This includes everything from choosing the right material to fabricating the enclosure itself. These six electrical panel enclosure design guidelines will ensure your precious equipment reaches the life expectancy you have in mind. A good design accounts for regulatory and application needs both physical and electrical: 1. Ratings & Standards.Chris Lloyd explains the basic decisions which need to be made when specifying an enclosure and how the right choice can reduce installation time and cost, and improve reliability. Whether you're an electrical installer, design engineer or an OEM, the chances are that you deal with electrical enclosures on a day-to-day basis. An enclosure has two basic tasks: housing and protecting sensitive electrical equipment from environmental contaminants and weather. Enclosures have volume and take up valuable space for.

Electrical Enclosure Design. You always have to ensure the design of your electrical enclosure is compatible with the different environments in which you install them. For instance, installing in high-temperature applications, you must ensure that all the components can withstand the temperature. Properly selecting an electrical enclosure for your application doesn’t need to be complicated, but it does require careful investigation and decision making. Also, many of the choices relating to enclosure types, sizes, ratings, materials and .An electrical enclosure is a purpose-built cabinet designed to house electrical and electronic devices, providing the required protection to keep operators/personnel safe from electrical shock hazards and devices protected from hazardous environments as well as accidentalDesigning enclosures is a critical aspect of creating electronic devices, machines and systems. These systems or machines could be various testing & measuring equipment, medical devices, consumer electronics, diagnostic equipment and so on.

Key steps to consider for main electrical enclosure design: component selection; enclosure type and size; component layout; safety and regulations. Key code areas in NEC and NFPA 79: general operating conditions; protection from electric shock; protection of equipment; grounding; conductors and cables; wiring practices; marking and safety signs .

thermal insulation for electrical enclosures

pcb enclosure design guidelines

As a first step in designing an enclosure, you need to choose the type of metal you will use and its thickness. Protocase stocks all of the metals generally used to make enclosures, including aluminum, stainless steel, carbon steel (cold-rolled steel or galvanneal) and copper. Electrical enclosure design includes all the steps involved in creating housing for electrical components. This includes everything from choosing the right material to fabricating the enclosure itself.

These six electrical panel enclosure design guidelines will ensure your precious equipment reaches the life expectancy you have in mind. A good design accounts for regulatory and application needs both physical and electrical: 1. Ratings & Standards.

Chris Lloyd explains the basic decisions which need to be made when specifying an enclosure and how the right choice can reduce installation time and cost, and improve reliability. Whether you're an electrical installer, design engineer or an OEM, the chances are that you deal with electrical enclosures on a day-to-day basis. An enclosure has two basic tasks: housing and protecting sensitive electrical equipment from environmental contaminants and weather. Enclosures have volume and take up valuable space for. Electrical Enclosure Design. You always have to ensure the design of your electrical enclosure is compatible with the different environments in which you install them. For instance, installing in high-temperature applications, you must ensure that all the components can withstand the temperature.

inside of industrial electrical cabinet

metal fabrication shops in houston tx

Waterproof Outdoor Project ABS Plastic Junction Box IP67 Weatherproof Dustproof Enclosure with Hinged Cover, Mounting Plate,Wall Brackets for Power Project (8.7"X6.7"X4.5")

electrical enclosures design|inside of industrial electrical cabinet