cnc and additive manufacturing Additive Manufacturing (AM) and CNC Machining can be combined together. Additive Manufactured parts can respond under stress differently than on-the-shelf materials due to the inner structure. With Additive Manufacturing (AM) . Call today and we will be there to handle your roofing and sheet metal needs! .

0 · difference between cnc and am

1 · cnc manufacturing vs additive manufacturing

2 · cnc machining vs am

3 · cnc machining additive powder

4 · additive manufacturing subtractive

5 · additive manufacturing services

6 · 3d printing vs additive manufacturing

7 · 3d printing additive powder

Vapor Seal air-sealed electrical boxes are designed for use in energy efficient homes to seal exterior walls and ceilings per required construction methods.

difference between cnc and am

Additive Manufacturing (AM) and CNC Machining can be combined together. Additive Manufactured parts can respond under stress differently than on-the-shelf materials due to the inner structure. With Additive Manufacturing (AM) .

cnc manufacturing vs additive manufacturing

For Keselowski Advanced Manufacturing (KAM), success with additive manufacturing happens on the so-called “subtractive” machines. The Statesville, North Carolina, company produces highly engineered metal .Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is .

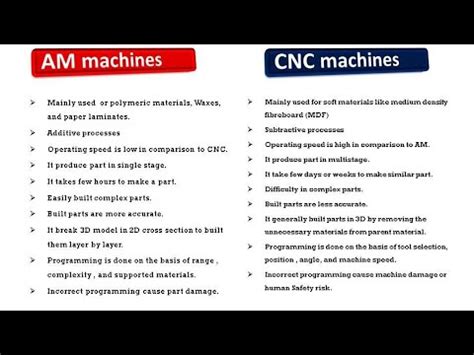

Manufacturing in the modern age is overshadowed by an ongoing debate between two distinct but interwoven forces - CNC Subtractive Manufacturing (CSM) and Additive Manufacturing (AM). This article delves into an analysis of . The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while CNC machining subtracts material to achieve high precision, repeatability, and smooth finishes in production.Additive Manufacturing (AM) and CNC Machining can be combined together. Additive Manufactured parts can respond under stress differently than on-the-shelf materials due to the inner structure. With Additive Manufacturing (AM) material shaping process can be long.

While both additive manufacturing and CNC machining work with metal to produce components, there are significant differences. Explore the processes & find which is best for your production.

For Keselowski Advanced Manufacturing (KAM), success with additive manufacturing happens on the so-called “subtractive” machines. The Statesville, North Carolina, company produces highly engineered metal components for industries including aerospace and defense through laser powder bed fusion (LPBF) on 20 metal additive machines.Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is crucial for businesses and designers looking to improve their new product development processes.

cnc machining vs am

cnc machining additive powder

what idoes omni metal dental brackets

Manufacturing in the modern age is overshadowed by an ongoing debate between two distinct but interwoven forces - CNC Subtractive Manufacturing (CSM) and Additive Manufacturing (AM). This article delves into an analysis of these two approaches, highlighting their respective strengths, and weaknesses, and exploring the burgeoning field of .

Here is a look at just some of the ways additive and machining interrelate right now. A donut-shaped machine tool component called the AKZ FDS adapter illustrates the increasingly intricate links between additive manufacturing (AM) and CNC machining. A version of this article was our cover story in the December 2022 issue of Modern Machine Shop.

CNC machining and additive manufacturing are two distinct manufacturing techniques that are widely used in the production of parts and components. CNC machining involves the use of computer-controlled machines to remove material from raw materials, such as metal or plastic, to create a final product.Additive manufacturing is more resource-friendly as it uses less material compared to CNC machining. In AM, material is only added where it's needed, reducing waste. CNC machining removes material from the workpiece, resulting in excess waste.

Additive manufacturing and CNC manufacturing are two popular production techniques that produce precise and functional metal parts fast and efficiently. Both are powerful and sophisticated manufacturing resources that bring any design concept to life. The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while CNC machining subtracts material to achieve high precision, repeatability, and smooth finishes in production.

Additive Manufacturing (AM) and CNC Machining can be combined together. Additive Manufactured parts can respond under stress differently than on-the-shelf materials due to the inner structure. With Additive Manufacturing (AM) material shaping process can be long. While both additive manufacturing and CNC machining work with metal to produce components, there are significant differences. Explore the processes & find which is best for your production. For Keselowski Advanced Manufacturing (KAM), success with additive manufacturing happens on the so-called “subtractive” machines. The Statesville, North Carolina, company produces highly engineered metal components for industries including aerospace and defense through laser powder bed fusion (LPBF) on 20 metal additive machines.

Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is crucial for businesses and designers looking to improve their new product development processes.Manufacturing in the modern age is overshadowed by an ongoing debate between two distinct but interwoven forces - CNC Subtractive Manufacturing (CSM) and Additive Manufacturing (AM). This article delves into an analysis of these two approaches, highlighting their respective strengths, and weaknesses, and exploring the burgeoning field of . Here is a look at just some of the ways additive and machining interrelate right now. A donut-shaped machine tool component called the AKZ FDS adapter illustrates the increasingly intricate links between additive manufacturing (AM) and CNC machining. A version of this article was our cover story in the December 2022 issue of Modern Machine Shop.

CNC machining and additive manufacturing are two distinct manufacturing techniques that are widely used in the production of parts and components. CNC machining involves the use of computer-controlled machines to remove material from raw materials, such as metal or plastic, to create a final product.Additive manufacturing is more resource-friendly as it uses less material compared to CNC machining. In AM, material is only added where it's needed, reducing waste. CNC machining removes material from the workpiece, resulting in excess waste.

additive manufacturing subtractive

additive manufacturing services

No-Sew Option to Attach Sides, Top, and Bottom of Liner to Shade: Start with either the top or bottom of your liner and attach the velcro or double-sided tape at the very edge of the fabric (basically, along the hemmed area). Then remove any backing on the tape/velcro, pull the fabric taut, and carefully press the fabric to the shade to secure.

cnc and additive manufacturing|difference between cnc and am