build your own wood cnc machine Before getting hands-on with your DIY wood CNC machine, you'll need to gather the necessary materials and tools. We'll provide you with a comprehensive checklist of everything you need, . The device face itself is 2.78" by 1.625". Each yoke (save for a rare few large receptacles that take up two gangs) mounts to a gang-- the space in a device box reserved for a single wiring device. This is how rectangular boxes are measured -- .

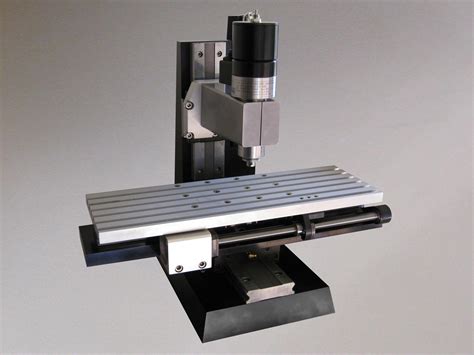

0 · make your own cnc mill

1 · homemade cnc milling machine plans

2 · homemade cnc mill

3 · homemade cnc machine plans

4 · home built cnc milling machine

5 · do it yourself cnc machine

6 · build it yourself cnc router

7 · best cnc router for beginners

What does a CNC operator do? A CNC operator pushes buttons to keep the CNC machines running while performing basic inspection of the machined parts. As an entry-level position, all of the skills necessary for a CNC operator to possess would be taught to a .

Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress . A compact router, baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer .While purchasing a ready-made CNC machine may seem like the easiest option, building your own DIY wood CNC machine can be a rewarding and cost-effective choice. In this guide, we . A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.

Before getting hands-on with your DIY wood CNC machine, you'll need to gather the necessary materials and tools. We'll provide you with a comprehensive checklist of everything you need, .DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a documentation of how I built my CNC and is not to be .Luckily, with a little bit of DIY spirit and some basic knowledge, you can build your own CNC machine tailored to your specific woodworking needs. In this blog post, we will guide you .

Baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer-controlled router. This project is ideal for tech-savvy woodworkers looking to add a CNC router to their shop or .Here are a few steps that will help you build your own CNC router and allow you to work on intricate woodworking projects: What specifications are you looking at? If the market for CNC machines are full of a wide range in size, you can .Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This

make your own cnc mill

Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it has a nice 43mm clamping flange. A compact router, baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer-controlled router. This project is ideal for tech-savvy woodworkers looking to add a CNC router to their shop or beginners who want to give this type of woodworking technology a try.While purchasing a ready-made CNC machine may seem like the easiest option, building your own DIY wood CNC machine can be a rewarding and cost-effective choice. In this guide, we will walk you through the process of creating your very own CNC machine from scratch.

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Before getting hands-on with your DIY wood CNC machine, you'll need to gather the necessary materials and tools. We'll provide you with a comprehensive checklist of everything you need, such as wood, electrical components, motors, bearings, threaded rods, and more.

welding entire sheets of sheet metal

DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a documentation of how I built my CNC and is not to be mistaken as a tutorial for buidling a CNC.Luckily, with a little bit of DIY spirit and some basic knowledge, you can build your own CNC machine tailored to your specific woodworking needs. In this blog post, we will guide you through the process of building your DIY CNC machine for woodworking, step-by-step.Baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer-controlled router. This project is ideal for tech-savvy woodworkers looking to add a CNC router to their shop or beginners who want to give this type of woodworking technology a try.Here are a few steps that will help you build your own CNC router and allow you to work on intricate woodworking projects: What specifications are you looking at? If the market for CNC machines are full of a wide range in size, you can choose to .

Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. ThisMost homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it has a nice 43mm clamping flange. A compact router, baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer-controlled router. This project is ideal for tech-savvy woodworkers looking to add a CNC router to their shop or beginners who want to give this type of woodworking technology a try.

While purchasing a ready-made CNC machine may seem like the easiest option, building your own DIY wood CNC machine can be a rewarding and cost-effective choice. In this guide, we will walk you through the process of creating your very own CNC machine from scratch.

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Before getting hands-on with your DIY wood CNC machine, you'll need to gather the necessary materials and tools. We'll provide you with a comprehensive checklist of everything you need, such as wood, electrical components, motors, bearings, threaded rods, and more.DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a documentation of how I built my CNC and is not to be mistaken as a tutorial for buidling a CNC.Luckily, with a little bit of DIY spirit and some basic knowledge, you can build your own CNC machine tailored to your specific woodworking needs. In this blog post, we will guide you through the process of building your DIY CNC machine for woodworking, step-by-step.

Baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer-controlled router. This project is ideal for tech-savvy woodworkers looking to add a CNC router to their shop or beginners who want to give this type of woodworking technology a try.

homemade cnc milling machine plans

welded steel modular storage cabinets

welding and metal fabrications

• Tubular bridges• Box girder bridges See more

build your own wood cnc machine|make your own cnc mill