carbide tool regrinding cnc machine The Star NXT CNC 5-axis tool and cutter grinding system provides a large grind zone that enables manufacturers to run both small and large diameter tools, . Joisyoya Outdoor Electrical Box Waterproof, IP67 Plastic Weatherproof Junction Box Enclosure with Mounting Plate, Wall Brackets, Cable Glands, for WiFi Electronics Project (5.9"x5.9"x3.5") - Amazon.com

0 · widma cnc tool grinder

1 · diamond wheels for carbide grinding

2 · cnc tool grinding machine

3 · carbide tool grinding wheels

4 · carbide grinding tool

5 · carbide cutter grinding machine

6 · carbide cutter grinder reviews

7 · carbide bench grinder

Check out our list of the best outdoor storage cabinets available online. All these options will stand to the test of time and weather conditions. We’re certain you’ll find something here that fits across all your requirements. 1. Rubbermaid Outdoor Storage Cabinet. The Rubbermaid outdoor Outdoor storage shed is waterproof and sturdy.

Carbide tool grinding is an essential process in CNC machining. It plays a crucial role in achieving high-quality machined parts with precision and accuracy. In this comprehensive guide, we will explore the types of grinding .Our CNC grinding machines are world-class tool grinders for production and re-sharpening, from entry-level model to high-end solution. With the HELITRONIC MINI PLUS tool grinding machine, tools with small and medium diameters can .The Star NXT CNC 5-axis tool and cutter grinding system provides a large grind zone that enables manufacturers to run both small and large diameter tools, .

how to secure outside electrical box from unauthorized use

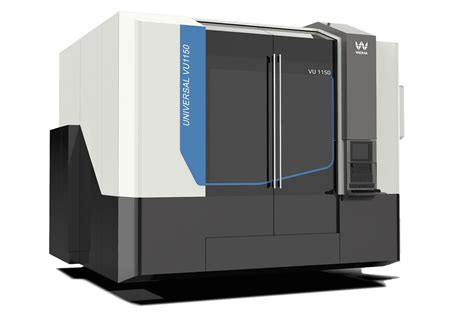

WIDMA manufactures cutting-edge CNC tool grinding machines for manufacturing & regrinding carbides and HSS tools. Used for regrind drills, end mills, reamers, etc.The VGrind 360S – the new standard for the complete machining of solid carbide tools of up to 200 mm. Ideal for applications in the areas of automotive manufacturing, toolmaking, medical .CNC Tool grinding and Form Grinding Machines: Our CNC Tool grinding machines with their 4. 5 or 6 axes are used for high precision and flexible grinding of cutting geometries in carbide, .Tools made of HSS (high speed steel) are sharpened using grinding wheels made of materials such as CBN or corundum. Diamond grinding wheels are used for tools made of carbide. In addition, modern tool grinding machines require .

Boost your Swiss CNC machining with expert carbide tool grinding. Discover the right equipment, grinding wheels, and optimization techniques. Click to learn more!

We have 5 late model 5 axis CNC ANCA Tool Grinders to insure your getting the best Performance and life out of your cutting tools. We specialize in the regrinding of all types of Carbide and HSS tooling such as End Mills, Drills, Reamers, .Regrinding carbide inserts offers a significant opportunity to reduce tooling costs and promote sustainability in machining operations. With careful planning, proper tool management, and . Carbide tool grinding is an essential process in CNC machining. It plays a crucial role in achieving high-quality machined parts with precision and accuracy. In this comprehensive guide, we will explore the types of grinding equipment, advantages and limitations of each type, and grinding wheel selection.

Our CNC grinding machines are world-class tool grinders for production and re-sharpening, from entry-level model to high-end solution. With the HELITRONIC MINI PLUS tool grinding machine, tools with small and medium diameters can be flexibly produced and resharpened.The Star NXT CNC 5-axis tool and cutter grinding system provides a large grind zone that enables manufacturers to run both small and large diameter tools, yet is packaged in a cost-effective compact footprint.WIDMA manufactures cutting-edge CNC tool grinding machines for manufacturing & regrinding carbides and HSS tools. Used for regrind drills, end mills, reamers, etc.The VGrind 360S – the new standard for the complete machining of solid carbide tools of up to 200 mm. Ideal for applications in the areas of automotive manufacturing, toolmaking, medical technology, precision engineering, aeronautical engineering and many more.

CNC Tool grinding and Form Grinding Machines: Our CNC Tool grinding machines with their 4. 5 or 6 axes are used for high precision and flexible grinding of cutting geometries in carbide, cermet, ceramic, PCB and PCD. Profimach tool grinding machines .

Tools made of HSS (high speed steel) are sharpened using grinding wheels made of materials such as CBN or corundum. Diamond grinding wheels are used for tools made of carbide. In addition, modern tool grinding machines require the ability to process cutting tools using high-performance mineral oil-based cooling lubricants that are not water . Boost your Swiss CNC machining with expert carbide tool grinding. Discover the right equipment, grinding wheels, and optimization techniques. Click to learn more!We have 5 late model 5 axis CNC ANCA Tool Grinders to insure your getting the best Performance and life out of your cutting tools. We specialize in the regrinding of all types of Carbide and HSS tooling such as End Mills, Drills, Reamers, Step Tools, Milling Cutters, Etc.

Regrinding carbide inserts offers a significant opportunity to reduce tooling costs and promote sustainability in machining operations. With careful planning, proper tool management, and adherence to best practices, companies can successfully implement a regrinding program.

Carbide tool grinding is an essential process in CNC machining. It plays a crucial role in achieving high-quality machined parts with precision and accuracy. In this comprehensive guide, we will explore the types of grinding equipment, advantages and limitations of each type, and grinding wheel selection.Our CNC grinding machines are world-class tool grinders for production and re-sharpening, from entry-level model to high-end solution. With the HELITRONIC MINI PLUS tool grinding machine, tools with small and medium diameters can be flexibly produced and resharpened.

The Star NXT CNC 5-axis tool and cutter grinding system provides a large grind zone that enables manufacturers to run both small and large diameter tools, yet is packaged in a cost-effective compact footprint.WIDMA manufactures cutting-edge CNC tool grinding machines for manufacturing & regrinding carbides and HSS tools. Used for regrind drills, end mills, reamers, etc.The VGrind 360S – the new standard for the complete machining of solid carbide tools of up to 200 mm. Ideal for applications in the areas of automotive manufacturing, toolmaking, medical technology, precision engineering, aeronautical engineering and many more.CNC Tool grinding and Form Grinding Machines: Our CNC Tool grinding machines with their 4. 5 or 6 axes are used for high precision and flexible grinding of cutting geometries in carbide, cermet, ceramic, PCB and PCD. Profimach tool grinding machines .

Tools made of HSS (high speed steel) are sharpened using grinding wheels made of materials such as CBN or corundum. Diamond grinding wheels are used for tools made of carbide. In addition, modern tool grinding machines require the ability to process cutting tools using high-performance mineral oil-based cooling lubricants that are not water . Boost your Swiss CNC machining with expert carbide tool grinding. Discover the right equipment, grinding wheels, and optimization techniques. Click to learn more!We have 5 late model 5 axis CNC ANCA Tool Grinders to insure your getting the best Performance and life out of your cutting tools. We specialize in the regrinding of all types of Carbide and HSS tooling such as End Mills, Drills, Reamers, Step Tools, Milling Cutters, Etc.

how to stack metal paper racks with metal brackets

widma cnc tool grinder

how to set work offset in cnc machine

diamond wheels for carbide grinding

cnc tool grinding machine

This category contains weatherproof boxes, enclosures, covers and accessories to keep your electrical boxes safe from storms, moisture, snow and other weather conditions which may harm electrical components.

carbide tool regrinding cnc machine|cnc tool grinding machine