cnc lathe machine working principle pdf What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the . This article overviews outdoor light junction boxes and details the many junction boxes available. By understanding more about outdoor light junction boxes, you can choose the right type for your needs and ensure that your outdoor lighting system functions properly.

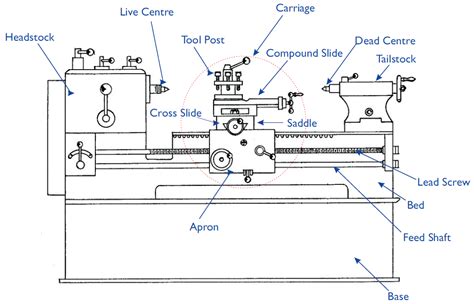

0 · sketch of a lathe machine

1 · simple diagram of lathe machine

2 · parts of lathe machine diagram

3 · operations performed on lathe machine

4 · lathe machine specification with diagram

5 · lathe machine schematic diagram

6 · labelled diagram of lathe machine

7 · block diagram of lathe machine

Desktops, shelving, counter tops, even flooring are held up with a bracket of some type. So you decided to design your own sheet metal part. Use the following simple guidelines to formulate and design the type of sheet metal bracket you will need to successfully meet your requirements.

Computer Numerical Control (CNC) mills and lathes. This course bridges the gap between what persons with a technical education know and what they must learn to begin using machine .This programming workbook provides basic principles necessary to program the Haas lathe. It is not intended as an in-depth study of all ranges of the machine use.This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by .

A CNC lathe holds cutting tools with a tool post similar to that used on a manual lathe.What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the .The applications of CNC include both for machine tool as well as non-machine tool areas. In the machine tool category, CNC is widely used for lathe, drill press, milling machine, grinding unit, .

11. Application of CNC Machine Tools The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC .What is a CNC Machine? symbols. machine tools like lathes, mills and grinders. Why is CNC Machining necessary? close tolerances. It consists of a screw spindle, a nut, balls and .

How CNC Lathe Works: Controlled by G and M codes. These are number values and co -ordinates. Each number or code is assigned to a particular operation. Typed in manually to . In this article, you’ll learn what is CNC machine is with its working principle, basic elements, advantages, applications, and PDF that you can download at the end of the article. What is a CNC Machine? In a CNC machine, all the numerical functions are controlled by .Computer Numerical Control (CNC) mills and lathes. This course bridges the gap between what persons with a technical education know and what they must learn to begin using machine toolsCNC.

sketch of a lathe machine

This programming workbook provides basic principles necessary to program the Haas lathe. It is not intended as an in-depth study of all ranges of the machine use.This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability.A CNC lathe holds cutting tools with a tool post similar to that used on a manual lathe.What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.

The applications of CNC include both for machine tool as well as non-machine tool areas. In the machine tool category, CNC is widely used for lathe, drill press, milling machine, grinding unit, laser, sheet-metal press working machine, tube bending machine etc. Highly11. Application of CNC Machine Tools The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining (EDM) CNC grinding machines CNC cutting machines (laser, plasma, electron, or flame)

What is a CNC Machine? symbols. machine tools like lathes, mills and grinders. Why is CNC Machining necessary? close tolerances. It consists of a screw spindle, a nut, balls and integrated ball return mechanism a shown in Figure . The flanged nut is .

How CNC Lathe Works: Controlled by G and M codes. These are number values and co -ordinates. Each number or code is assigned to a particular operation. Typed in manually to CAD/CAM by machine operators. G&M codes are automatically generated by the . In this article, you’ll learn what is CNC machine is with its working principle, basic elements, advantages, applications, and PDF that you can download at the end of the article. What is a CNC Machine? In a CNC machine, all the numerical functions are controlled by .Computer Numerical Control (CNC) mills and lathes. This course bridges the gap between what persons with a technical education know and what they must learn to begin using machine toolsCNC.

This programming workbook provides basic principles necessary to program the Haas lathe. It is not intended as an in-depth study of all ranges of the machine use.This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability.

A CNC lathe holds cutting tools with a tool post similar to that used on a manual lathe.What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.

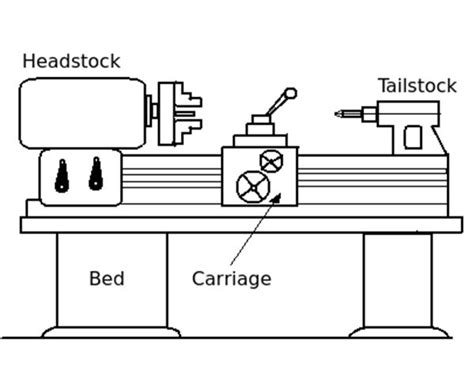

simple diagram of lathe machine

The applications of CNC include both for machine tool as well as non-machine tool areas. In the machine tool category, CNC is widely used for lathe, drill press, milling machine, grinding unit, laser, sheet-metal press working machine, tube bending machine etc. Highly11. Application of CNC Machine Tools The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining (EDM) CNC grinding machines CNC cutting machines (laser, plasma, electron, or flame)What is a CNC Machine? symbols. machine tools like lathes, mills and grinders. Why is CNC Machining necessary? close tolerances. It consists of a screw spindle, a nut, balls and integrated ball return mechanism a shown in Figure . The flanged nut is .

china sheet metal screws

china stainless steel bento lunch box quotes

There are numerous types of edges, joints, seams, and notches used to join sheet-metal work. We will discuss those that are most often used. Edges are formed to enhance the appearance of the work, to strengthen the piece, and to eliminate the cutting hazard of the raw edge.

cnc lathe machine working principle pdf|simple diagram of lathe machine