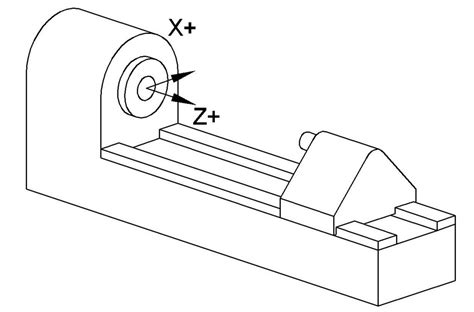

cnc lathe machine x and z axis Depending on the type of machine and the work envelope’s orientation (i.e., horizontal or vertical), these two axes can be a combination of the x-axis and y-axis, the x-axis and z-axis, or the y-axis and the z-axis. L&T 16 WAY SPN DB TRIPBOX Distribution Board at best prices with FREE shipping & cash on delivery. Only Genuine Products. 30 Day Replacement Guarantee.

0 · machining lathe axis diagram

1 · lathe axis explained

2 · cnc mill axis diagram

3 · cnc machine axis locations diagram

4 · cnc lathe axis explained

5 · cnc lathe axis directions

6 · cnc axis chart

7 · axis identification in cnc machine

Happy New Year! We look forward to what this year brings. Thank you to this crew for their hard work, always! You are the best of the best!

Using an X, Y or Z code in a CNC program tells the machine to go to a specific location along those axes. Location changes can be in one or more axes. If only a Z axis . The most common configuration for a CNC lathe is two-axis, known as X-axis and Z-axis. The X-axis is the horizontal axis, which runs parallel to the lathe spindle. This axis controls the longitudinal movement of the cutting tool, allowing it . Using an X, Y or Z code in a CNC program tells the machine to go to a specific location along those axes. Location changes can be in one or more axes. If only a Z axis coordinate is given then the machine will only move in the Z axis. While simpler CNC lathes typically operate with two primary axes (X and Z), more advanced models can incorporate additional axes for enhanced functionality. For example: Two-axis lathe: Features X (radial) and Z (longitudinal) axes; Three-axis lathe: Adds a C-axis for rotary motion of the spindle

machining lathe axis diagram

lathe axis explained

Depending on the type of machine and the work envelope’s orientation (i.e., horizontal or vertical), these two axes can be a combination of the x-axis and y-axis, the x-axis and z-axis, or the y-axis and the z-axis. How is the z-axis different from the x-axis on a lathe? The z-axis and x-axis are two essential components of a lathe machine. They play a crucial role in the machining process and determine the movement and positioning of the tool and workpiece.

CNC lathe machines come in various types, each designed to meet specific machining needs. Let’s break them down: 2-Axis CNC Lathe. A 2-axis CNC lathe is the most basic type. It operates with two linear axes: X and Z. The X-axis controls the diameter, while the Z-axis controls the length. Applications:

Simple CNC Lathes use a Z-axis, which is parallel to the spindle axis, and an X-axis, which is at right angles to the spindle. In G-Wizard Editor/Simulator, the display looks like this: X-Axis runs top to bottom while Z-axis runs left and right.

One crucial element of CNC machines is the Z-axis, which plays a pivotal role in determining the vertical direction of the tool. In this blog post, we will explore the Z-axis direction in CNC machines, its significance, and how it affects the manufacturing process. Defining the Z .For an N/C lathe, the positive cutting tool motion directions are away from the headstock, usually to the right (Z-axis), and away from the spindle's axis (X-axis). For tool-in-the-rear machines, the X-plus direction is away from the operator.If we speak in general terms, a CNC machine has a minimum of 2 axes which operates along the X, Z plane. X axis denotes the vertical plane and Z axis represents depth. But 3-axis CNC lathes are more versatile.

The most common configuration for a CNC lathe is two-axis, known as X-axis and Z-axis. The X-axis is the horizontal axis, which runs parallel to the lathe spindle. This axis controls the longitudinal movement of the cutting tool, allowing it .

Using an X, Y or Z code in a CNC program tells the machine to go to a specific location along those axes. Location changes can be in one or more axes. If only a Z axis coordinate is given then the machine will only move in the Z axis. While simpler CNC lathes typically operate with two primary axes (X and Z), more advanced models can incorporate additional axes for enhanced functionality. For example: Two-axis lathe: Features X (radial) and Z (longitudinal) axes; Three-axis lathe: Adds a C-axis for rotary motion of the spindle Depending on the type of machine and the work envelope’s orientation (i.e., horizontal or vertical), these two axes can be a combination of the x-axis and y-axis, the x-axis and z-axis, or the y-axis and the z-axis. How is the z-axis different from the x-axis on a lathe? The z-axis and x-axis are two essential components of a lathe machine. They play a crucial role in the machining process and determine the movement and positioning of the tool and workpiece.

CNC lathe machines come in various types, each designed to meet specific machining needs. Let’s break them down: 2-Axis CNC Lathe. A 2-axis CNC lathe is the most basic type. It operates with two linear axes: X and Z. The X-axis controls the diameter, while the Z-axis controls the length. Applications: Simple CNC Lathes use a Z-axis, which is parallel to the spindle axis, and an X-axis, which is at right angles to the spindle. In G-Wizard Editor/Simulator, the display looks like this: X-Axis runs top to bottom while Z-axis runs left and right.One crucial element of CNC machines is the Z-axis, which plays a pivotal role in determining the vertical direction of the tool. In this blog post, we will explore the Z-axis direction in CNC machines, its significance, and how it affects the manufacturing process. Defining the Z .

cnc mill axis diagram

For an N/C lathe, the positive cutting tool motion directions are away from the headstock, usually to the right (Z-axis), and away from the spindle's axis (X-axis). For tool-in-the-rear machines, the X-plus direction is away from the operator.

Can You Put A Doorbell Transformer In A Junction Box? So long as you keep this device outside the junction box, you should be fine. And if you must install the transformer in a junction box, don’t forget to separate the high and low-voltage wires.

cnc lathe machine x and z axis|cnc machine axis locations diagram