electric vehicle battery box design DuPont’s 3-in-1 battery-box concept unveiled in late 2022 is a new example of modular design that consolidates cell cooling, electrical interconnection, and structural . $35.00

0 · sae ev battery box

1 · high voltage battery box design

2 · ev battery junction box

3 · ev battery boxes

4 · electric car battery box

5 · battle for the ev battery box

6 · battery box extrusion

7 · aluminum ev battery box

Check out our metal butterfly music box selection for the very best in unique or custom, handmade pieces from our music boxes shops.

DuPont’s 3-in-1 battery-box concept unveiled in late 2022 is a new example of modular design that consolidates cell cooling, electrical interconnection, and structural .A battery enclosure that features a single-piece, metal-reinforced composite tray .Figure 1 presents a typical BMS architecture containing a battery management unit (BMU), cell supervisor unit (CMU) and a battery junction box (BJB). A BMU typically has a microcontroller .

Growth from 2020 onwards is driven by substitution of steel in platform parts as well as through significantly higher aluminum content of battery electric vehicles, BEVs use more than three .

A battery enclosure that features a single-piece, metal-reinforced composite tray and one-piece composite cover is a step closer to an electric vehicle (EV) production application. EV battery box designs are structures that enclose the battery. They protect the vehicle’s powerhouse from external interference, such as in a car crash. Some may act as insulators or contribute to the battery’s cooling system.The Docol EV Design Concept demonstrates ways to cost-effectively improve the safety, weight, and space utilization of electric vehicles, optimizing body geometries with AHSS steels for the most important load paths.

Overall, CSP reports that its multi-material battery enclosure is about 15% lighter than a steel battery box, with better temperature resistance compared to aluminum. Next-level innovations: Clips, impact shields, full .Aiming to the lightweight design of the battery box for electric vehicle, this paper research the design process and the strength analysis method of long carbon fiber reinforced thermoplastic . DuPont’s 3-in-1 battery-box concept unveiled in late 2022 is a new example of modular design that consolidates cell cooling, electrical interconnection, and structural components. Its housing is made of the company’s Zytel HTN, a nylon-based polyamide capable of resisting high temperatures.The battery box consists of four primary structural pieces: top cover, bottom cover, internal structure, and side impact crash protection structure. In the image below, the primary load-bearing structural components are identified as the crash structure and the battery frame.

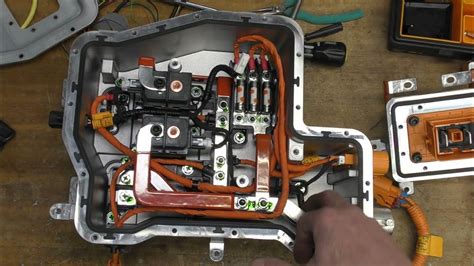

Figure 1 presents a typical BMS architecture containing a battery management unit (BMU), cell supervisor unit (CMU) and a battery junction box (BJB). A BMU typically has a microcontroller (MCU), which manages all of the functions within the battery pack.

sae ev battery box

Growth from 2020 onwards is driven by substitution of steel in platform parts as well as through significantly higher aluminum content of battery electric vehicles, BEVs use more than three times as much aluminum than non-BEVs in platform parts today. A battery enclosure that features a single-piece, metal-reinforced composite tray and one-piece composite cover is a step closer to an electric vehicle (EV) production application.

electric breaker box cover

EV battery box designs are structures that enclose the battery. They protect the vehicle’s powerhouse from external interference, such as in a car crash. Some may act as insulators or contribute to the battery’s cooling system.The Docol EV Design Concept demonstrates ways to cost-effectively improve the safety, weight, and space utilization of electric vehicles, optimizing body geometries with AHSS steels for the most important load paths. Overall, CSP reports that its multi-material battery enclosure is about 15% lighter than a steel battery box, with better temperature resistance compared to aluminum. Next-level innovations: Clips, impact shields, full-assembly capabilities. CSP continues to innovate its battery enclosure design, as well as its range of capabilities for customers.

Aiming to the lightweight design of the battery box for electric vehicle, this paper research the design process and the strength analysis method of long carbon fiber reinforced thermoplastic (LCFT) for a Learn how a novel electric vehicle (EV) capacitive-isolation daisy-chain data acquisition IC enables a streamlined junction box time-aligned with battery cell voltage and temperature measurements. DuPont’s 3-in-1 battery-box concept unveiled in late 2022 is a new example of modular design that consolidates cell cooling, electrical interconnection, and structural components. Its housing is made of the company’s Zytel HTN, a nylon-based polyamide capable of resisting high temperatures.

high voltage battery box design

The battery box consists of four primary structural pieces: top cover, bottom cover, internal structure, and side impact crash protection structure. In the image below, the primary load-bearing structural components are identified as the crash structure and the battery frame.Figure 1 presents a typical BMS architecture containing a battery management unit (BMU), cell supervisor unit (CMU) and a battery junction box (BJB). A BMU typically has a microcontroller (MCU), which manages all of the functions within the battery pack.

Growth from 2020 onwards is driven by substitution of steel in platform parts as well as through significantly higher aluminum content of battery electric vehicles, BEVs use more than three times as much aluminum than non-BEVs in platform parts today. A battery enclosure that features a single-piece, metal-reinforced composite tray and one-piece composite cover is a step closer to an electric vehicle (EV) production application.

EV battery box designs are structures that enclose the battery. They protect the vehicle’s powerhouse from external interference, such as in a car crash. Some may act as insulators or contribute to the battery’s cooling system.

The Docol EV Design Concept demonstrates ways to cost-effectively improve the safety, weight, and space utilization of electric vehicles, optimizing body geometries with AHSS steels for the most important load paths. Overall, CSP reports that its multi-material battery enclosure is about 15% lighter than a steel battery box, with better temperature resistance compared to aluminum. Next-level innovations: Clips, impact shields, full-assembly capabilities. CSP continues to innovate its battery enclosure design, as well as its range of capabilities for customers.

Aiming to the lightweight design of the battery box for electric vehicle, this paper research the design process and the strength analysis method of long carbon fiber reinforced thermoplastic (LCFT) for a

ev battery junction box

electric concrete saw 14 storage box for evolution

electric city boxing club great falls mt

$150.00

electric vehicle battery box design|high voltage battery box design