best file format for centroid cnc milling machines This comprehensive guide aims to demystify the selection process, providing valuable insights and recommendations for choosing the optimal file format for CNC machines. From common . Galvanizing with zinc to protect the base metal from rust was developed in France in 1837. By the 1850s the material was used on post offices and customhouses, as well as on train sheds and factories. In 1857 one of the first metal roofs in .

0 · cnc drawing cad files

1 · 3d machining cad files

$167.99

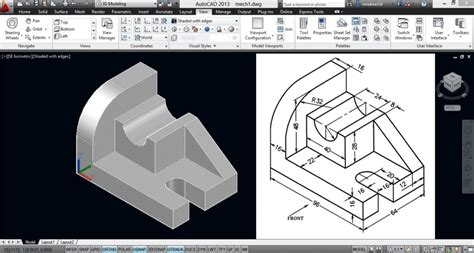

Master your CNC machining projects with the best CAD file formats. Different software programs generate specific file formats to transfer design data seamlessly into CNC systems. The integrity of CAD files directly influences the .

solar metal house number display

This comprehensive guide aims to demystify the selection process, providing valuable insights and recommendations for choosing the optimal file format for CNC machines. From common . Let’s decode the intricacies of some of the most popular CNC file formats in the industry. 1. DXF (Drawing Exchange Format) Originally introduced by Autodesk for their AutoCAD software, DXF files are a public standard for . Here’s a breakdown of the most common CAD file formats used in CNC machining, along with an explanation of how they work: 1. STL (Stereolithography) Description: The STL .

cnc drawing cad files

What are the best CNC machine file formats? When manufacturing parts using Computer-Aided Manufacturing (CAM), two file types are best suited for the job; these are STEP and IGES format. Using a CAM program, the . We cannot talk about CNC machining without mentioning CNC files — the digital blueprints that CNC machines utilize when cutting parts. This comprehensive article discusses .

By understanding the nuances of CNC machine file formats, you can enhance your manufacturing processes, improve efficiency, and achieve higher precision in your projects. Choose the right . Have you ever wondered how digital designs are transformed into high-precision machined parts? CAD (Computer-Aided Design) files are the key bridge in this process. CAD .There’s a range of different file format that comes to mind when you’re working in the CNC milling area. We’ve compiled them here with a quick roadmap on how to use them and how to bring . Whether it’s DXF files for 2D drawings, DWG files for intricate designs, STL files for 3D modeling, or the all-encompassing G-Code files, each file type plays a significant role in .

3d machining cad files

Master your CNC machining projects with the best CAD file formats. Different software programs generate specific file formats to transfer design data seamlessly into CNC systems. The integrity of CAD files directly influences the quality and accuracy of the final parts.

This comprehensive guide aims to demystify the selection process, providing valuable insights and recommendations for choosing the optimal file format for CNC machines. From common formats like G-code and DXF to emerging formats like STL and STEP, we will explore their features, advantages, and limitations.

Let’s decode the intricacies of some of the most popular CNC file formats in the industry. 1. DXF (Drawing Exchange Format) Originally introduced by Autodesk for their AutoCAD software, DXF files are a public standard for CAD data exchange.

Here’s a breakdown of the most common CAD file formats used in CNC machining, along with an explanation of how they work: 1. STL (Stereolithography) Description: The STL file format is one of the most widely used formats in 3D printing and CNC machining for additive manufacturing or rapid prototyping. What are the best CNC machine file formats? When manufacturing parts using Computer-Aided Manufacturing (CAM), two file types are best suited for the job; these are STEP and IGES format. Using a CAM program, the factory can use these file formats to . We cannot talk about CNC machining without mentioning CNC files — the digital blueprints that CNC machines utilize when cutting parts. This comprehensive article discusses the different CAD file formats used in CNC machining operations as well as their pros and cons.By understanding the nuances of CNC machine file formats, you can enhance your manufacturing processes, improve efficiency, and achieve higher precision in your projects. Choose the right file format based on your project requirements and stay updated on the latest trends in CNC machining technology.

Have you ever wondered how digital designs are transformed into high-precision machined parts? CAD (Computer-Aided Design) files are the key bridge in this process. CAD involves creating 2D and 3D models, with these files containing detailed geometric data to guide CNC machines in precise cutting, drilling, and grinding. Selecting the right file format .There’s a range of different file format that comes to mind when you’re working in the CNC milling area. We’ve compiled them here with a quick roadmap on how to use them and how to bring them to your workflow.

Whether it’s DXF files for 2D drawings, DWG files for intricate designs, STL files for 3D modeling, or the all-encompassing G-Code files, each file type plays a significant role in ensuring the CNC machine’s optimal performance and the creation of .Master your CNC machining projects with the best CAD file formats. Different software programs generate specific file formats to transfer design data seamlessly into CNC systems. The integrity of CAD files directly influences the quality and accuracy of the final parts.

This comprehensive guide aims to demystify the selection process, providing valuable insights and recommendations for choosing the optimal file format for CNC machines. From common formats like G-code and DXF to emerging formats like STL and STEP, we will explore their features, advantages, and limitations. Let’s decode the intricacies of some of the most popular CNC file formats in the industry. 1. DXF (Drawing Exchange Format) Originally introduced by Autodesk for their AutoCAD software, DXF files are a public standard for CAD data exchange. Here’s a breakdown of the most common CAD file formats used in CNC machining, along with an explanation of how they work: 1. STL (Stereolithography) Description: The STL file format is one of the most widely used formats in 3D printing and CNC machining for additive manufacturing or rapid prototyping.

What are the best CNC machine file formats? When manufacturing parts using Computer-Aided Manufacturing (CAM), two file types are best suited for the job; these are STEP and IGES format. Using a CAM program, the factory can use these file formats to .

We cannot talk about CNC machining without mentioning CNC files — the digital blueprints that CNC machines utilize when cutting parts. This comprehensive article discusses the different CAD file formats used in CNC machining operations as well as their pros and cons.By understanding the nuances of CNC machine file formats, you can enhance your manufacturing processes, improve efficiency, and achieve higher precision in your projects. Choose the right file format based on your project requirements and stay updated on the latest trends in CNC machining technology. Have you ever wondered how digital designs are transformed into high-precision machined parts? CAD (Computer-Aided Design) files are the key bridge in this process. CAD involves creating 2D and 3D models, with these files containing detailed geometric data to guide CNC machines in precise cutting, drilling, and grinding. Selecting the right file format .There’s a range of different file format that comes to mind when you’re working in the CNC milling area. We’ve compiled them here with a quick roadmap on how to use them and how to bring them to your workflow.

Where the wiring method is conduit, tubing, Type AC cable, Type MC cable, Type MI cable, nonmetallic-sheathed cable, or other cables, a box or conduit body shall be installed at each conductor splice point, outlet point, switch point, junction point, termination point, or pull point.A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings.

best file format for centroid cnc milling machines|cnc drawing cad files