cnc machinning and addiditve manufacturing CNC machining and additive manufacturing are two distinct manufacturing techniques that are widely used in the production of parts and components. CNC machining involves the use of computer-controlled . Send off your special photo gift in style with gift packaging, available at Walgreens. .

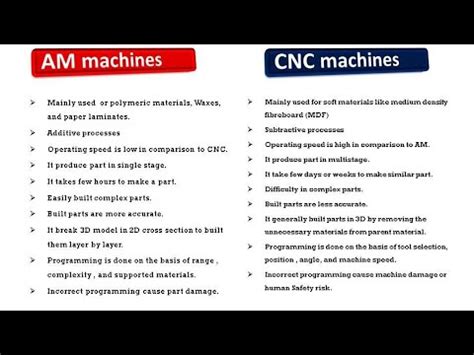

0 · difference between cnc and am

1 · cnc machining vs am

2 · cnc machining vs additive manufacturing

Keep your animals cool, dry, and protected from overheating and rain. Powder-coated mesh wire and galvanized steel prevent predators while allowing air circulation. This metal chicken coop has the strength to outlast harsh use. Spacious Pet Playpen: Small animals can enjoy space for .

Additive manufacturing offers greater design flexibility since it isn't constrained by the tool geometry or path. This enables the production of complex internal structures like lattice or .

austin electrical enclosures salaries

CNC machining and additive manufacturing are two distinct manufacturing techniques that are widely used in the production of parts and components. CNC machining involves the use of computer-controlled .For large-scale production and products that demand exceptional precision, CNC machining is often the go-to solution. On the other hand, when a rapid turnaround or customization is .Understanding Additive Manufacturing and CNC Machining. Cutting through the jargon, the essence of Additive Manufacturing (AM) and Computer Numerical Control (CNC) Machining rests on three core principles: design, production, .

Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is . A donut-shaped machine tool component called the AKZ FDS adapter illustrates the increasingly intricate links between additive manufacturing (AM) and CNC machining. A version of this article was our cover story in the .Additive manufacturing and CNC machining are two widely used methods, each with its own unique characteristics. This article aims to provide a comprehensive comparison between .

This hybrid CNC machine tool employs an additive process engineered for a specific purpose: Quickly producing steel tooling for injection molding. Liquid Metal + Laser Wire 3D Printing. . Additive Manufacturing is .

Using CNC Machining to Create Precise 3D Printed Parts. Looking at the chart above, you will notice that one of the key differences between additive manufacturing and subtractive manufacturing is the surface finish and .

The LASER EX super-multitasking machines perform laser metal deposition (LMD), hardening, subtractive machining and grinding all in one machine. . CNC Controls. OSP-P300; OSP-P500; Productivity. OSP suite; ECO suite plus .

Discover innovative hybrid additive manufacturing and CNC machines & learn about metal additive manufacturing and CNC machine 3D printers at Phillips Corporation. . an umbrella term that also includes some sculpting and welding machining. Additive Manufacturing consists of any process that increases the mass of a part. Processes like manual .CNC machining includes both additive and subtractive processes, each with distinct methodologies: . Additive Manufacturing: Refers to processes like 3D printing, where material is added layer by layer to build a part. This technique allows for greater design flexibility and reduces waste, making it ideal for complex geometries. .Meltio Engine CNC Integration Turn your existing FANUC i-Series CNC machine tool into a hybrid manufacturing system with no inherent size constraints. With the capability of integrating a Directed Energy Deposition (DED) head directly into a CNC machine we can build a part, then immediately move to a finishing process all in a single cycle.

By integrating additive manufacturing technology into multi-tasking machines and simultaneous 5-axis machining centers, it becomes possible to perform metal layering and finish machining all in one machine, greatly expanding the scope of metal processing. This article explores the differences between additive manufacturing and CNC machining, two different manufacturing processes used to create objects. While both processes have their strengths and weaknesses, choosing the right manufacturing process depends on the specific needs of the project.

Hybrid CNC machines represent a groundbreaking integration of additive manufacturing (3D printing) and subtractive machining (CNC milling). These advanced systems combine the precision of traditional CNC technology with the versatility and creativity of additive processes, resulting in a powerful and innovative manufacturing solution.CNC Machining is a subtractive manufacturing technology, where material is removed from a solid block, or workpiece, using various CNC machining equipment such as milling machines, lathes, and grinders. This process is known for its high precision and versatility in creating a wide range of materials, including metal, plastic, wood, foam, and . The environmental impacts of additive manufacturing vs. traditional machining via life cycle assessment were compared in a previous study , which indicates that the primary difference between AM and CNC machining is that the latter typically uses cutting oil for lubrication, an additional source of waste.What is CNC Machining? CNC Machining is a subtractive manufacturing process that employs pre-programmed computer software to control the movement of tools and machinery. The term 'subtractive' refers to the fact that this method involves removing material from a workpiece, in contrast to the layering process seen in additive manufacturing .

When comparing CNC machining and additive manufacturing in aerospace, you’ll find that each method excels in different areas. CNC machining offers high precision and consistency, making it ideal for stringent aerospace specifications and safety-critical components. Conversely, additive manufacturing shines in producing complex geometries and allows for .

Additive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video) For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

difference between cnc and am

A clever combination: Additive manufacturing and CNC machining. DMG MORI has been a successful player on the market since 2013 with its combination of laser deposition welding and machining on the LASERTEC DED hybrid series . CNC Machining Additive Manufacturing Integrated Approach; Material Utilization: Higher waste due to subtractive nature: Efficient use, layer by layer construction . The hybridization of CNC and additive manufacturing is . Additive Manufacturing is a process that uses 3D printing to create physical objects from a digital model. The process involves adding material in layers and using a fusing application, such as a heated printhead or laser, to .

CNC vs 3D printing: Additive vs subtractive manufacturing. Unlike 3D printing, CNC is subtractive rather than additive. The CNC process starts with a larger block of material as the workpiece, and removes areas, like chipping away at marble – to get to the final model. 3D printers instead use additive manufacturing technologies.Most often, and especially here I'm speaking of metal, knowing that AMT is largely a metal-oriented audience, parts get finished on a CNC machine. In fact, many estimate that it's a large percentage that go to a CNC machine, maybe as much as 95% or more of parts that are made in metal, 3D printed metal parts, go on for finishing in the machine. On the other hand, newer processes like CNC machining and additive manufacturing have virtually no barrier to entry: consumers can even order custom parts directly via third-party online bureaus. This article looks at six of the most common metal manufacturing processes, comparing their characteristics and respective pros and cons. .Integrated industrial metal 3D printing (Additive Manufacturing) and CNC machining. The XtenDED features a twin-head setup that combines the AMBIT laser processing head with the tool magazine of a CNC machine. The AMBIT head adds metal using powder-fed Laser Metal Deposition (LMD) which is a form of Directed Energy Deposition (DED) – where a .

A maker of CNC machine tools and a maker of AM technology come together to describe integrating additive and subtractive into an efficient process for production. . Additive Manufacturing is the media brand devoted to industrial applications of 3D printing technology. We cover everything from 3D printing news and product releases to expert .

Machining is the most common choice for low volume manufacturing because it is flexible, and can produce strong, accurate parts. Machining removes material from a workpiece (typically a billet) by cutting it with rotating tools (milling) or rotating the workpiece itself against a . Metal parts produced through additive manufacturing almost invariably need machining as a follow-up step. Only the subtractive process can achieve the most narrow tolerances and smoothest finishes. Far from being opposite or competitive processes, additive manufacturing and CNC machining actually go together. They belong in the same machine.

3D Printing Vs CNC Machining •The key difference between 3D printing and CNC machining is that 3D printing is a form of additive manufacturing, while the CNC machining is subtractive. •This means CNC machining starts with a block of material (called a blank), and cuts away material to create the finished part. To do this, cutters and spinningWhat is Additive manufacturing? Additive manufacturing (AM), which is also called 3D printing, is a process that makes 3D objects using 3d printing additive manufacturing.It does this by adding material one layer at a time. At first, this technology was used in additive manufacturing in the aerospace and medical industries.

CNC Machining External Inspection (CMM, gaging, etc.) Internal Inspection (CT scan, X-ray, etc.) Robotics & Automation Heat Treating . Additive Manufacturing is the media brand devoted to industrial applications of 3D printing technology. We cover everything from 3D printing news and product releases to expert interviews and in-depth .

cnc machining vs am

$65.65

cnc machinning and addiditve manufacturing|cnc machining vs additive manufacturing