cnc machining parameters throughput Reflect on the types of CNC boring machines that would best suit your applications, and think about the benefits of integrating CNC boring with other machining processes to enhance precision and efficiency. Key Parameters in CNC Boring. CNC boring is a precision machining process used to enlarge or refine pre-drilled holes to exact specifications.

Does anyone manufacture a selector switch box specifically designed for turntables, multiple turntables? A separate component as a hub for individual turntables, even when using a phono preamp, with or without ground wires, and RCA interconnects/cables/jacks.

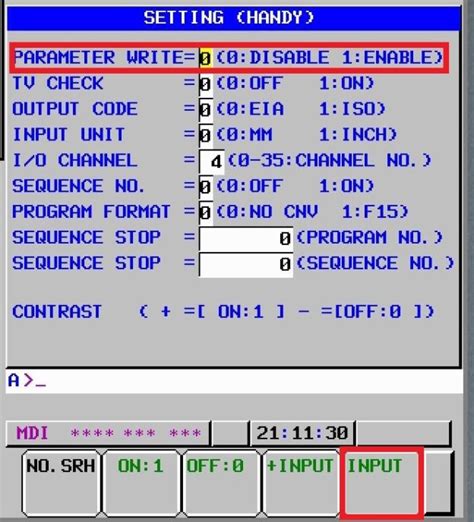

0 · data entry cnc parameter

1 · cnc parameters examples

2 · cnc parameters and functions

3 · cnc parameter settings

4 · cnc machining parameters list

5 · cnc machining parameters explained

6 · basic cnc parameters

7 · 7 cnc parameters

The Inside Setback is the distance from the apex of the inside mold lines to the tangent point of the inside radius. When the sheet metal is bent the inside radius pulls the edge of the material away from the apex of the bend.

Setting CNC machine parameters correctly is crucial for ensuring precision, efficiency, and the overall success of the machining process. The following eight steps outline the process from initialization to execution, .

Discover the critical distinctions between feed rate and cutting speed in CNC machining. Learn how adjusting these factors impacts material removal, surface finish, and tool lifespan, and . CNC Turning, or Computer Numerical Control Turning, is an important part of modern CNC machining processes and operations. . efficiency, and outcome of the machining process. Understanding these parameters is . Discover why CNC machining parameters are crucial for achieving precision, extending tool life, improving surface finish, and reducing production costs. Learn about the main parameters and best practices for optimizing your machining process. . Higher spindle speeds are typically used for softer materials, while lower speeds are suited for . Spindle speeds and feeds are crucial CNC machining parameters, defining the spindle’s revolutions per minute (RPM) and the tool’s advance rate into the material. These settings are vital for determining machining efficiency, surface finish, and tool life. 2. How do spindle speeds affect machining performance?

Reflect on the types of CNC boring machines that would best suit your applications, and think about the benefits of integrating CNC boring with other machining processes to enhance precision and efficiency. Key Parameters in CNC Boring. CNC boring is a precision machining process used to enlarge or refine pre-drilled holes to exact specifications.

data entry cnc parameter

cnc parameters examples

cnc machining parameters throughput. Processing technology: Turning,Milling,Planing,Grinding,Drilling,Etching / Chemical Machining: Heat treatment: Annealing, Normalizing , Nitriding, Tempering , Carbonitriding: Material Here’s a free Microsoft Excel workbook that facilitates the estimation and logging of CNC machining parameters and performance. The three tabs at the bottom left of the workbook access worksheets showing estimated parameters for a 60,000 RPM HF Spindle, the Makita 0701 Router, and Dewalt DWP611 Router in Shapeoko 3s. The maximum spindle/router speeds .Calculating Feeds and Speeds: Practical Examples Example 1: Milling Aluminum. To calculate feed rate (F) for milling aluminum, use the formula F = S \times N \times T, where S is the speed in surface feet per minute (SFM), N is the number of teeth on the cutter, and T is the chip load per tooth, typically around 0.005 inch. The limit of RPM on rigid tapping is something related to the processing time of the control and servo combinations. A key indicator of limit is, first RTFM. If not specific, consider the machine's rapid rates as a probable indicator of speeds. A machine that rapids at 740ipm probably can't tap at as high a speed as one equipped with 1260ipm .

Understanding CNC cutting speeds and feeds is essential for optimizing the performance of your CNC machining operations. These parameters directly affect tool life, material removal rate, and surface finish. Whether you’re working with CNC milled parts, CNC turned parts, or any other machined components, mastering speeds and feeds ensures . > Cutting Speed Chart for Different Materials in Turning, Drilling and More CNC Machining Processes | CNCLATHING. Home > Guide > Cutting Speed Chart for Different Materials in Turning, . multiply the listed speeds by a factor of 2 to 4, and the speed should be lower for carbon steel tool. . The text provides a holistic understanding of machining processes and machines in manufacturing; it enables critical thinking through mathematical modeling and problem solving, and offers 200 .

A low surface finish obtained from machining processes significantly enhances corrosion resistance, fatigue strength, creep life, and a variety of other functional properties [25]. The optimization of machining parameters is a constant technical activity whose goals are to lower production costs while producing the desired result quality.Explore the essential differences between CNC machining vs manual machining, including precision, speed, and skill requirements for optimal use . heat, and other machining parameters. . setting cutting speeds and feeds, and adjusting .

cnc parameters and functions

Polyoxymethylene (POM), popularly known as Acetal or by trade names like Delrin, is very important in the manufacturing industry due to its strength, low friction, and dimensional stability.This guide simplifies the POM machining process by providing necessary techniques and tips geared towards CNC machines. We aim to provide you with the .Machining Calculators for CNC Operations: Speeds, Feeds, Spindle Speed, and Material Removal Rate Optimize your CNC machining and milling operations with our suite of free, interactive calculators designed to improve productivity and precision. This collection includes calculators for determining cutting speed, feed rate, spindle speed, and material removal rate .

About the Machining Doctor. At Machining Doctor, our mission is to serve the machining industry as a comprehensive and reliable source of technical information. We strive to be the go-to destination for professionals in the niche seeking information, knowledge, and expertise. Join us and stay ahead of the curve! Learn more This article will explore how to achieve this goal by optimizing the processing parameters of CNC turn-mill machine tools. First of all, choosing the right tool is a key step in optimizing processing parameters. High-performance tool materials, such as coated carbide, ceramic or diamond tools, can increase cutting speeds and tool life. In .CloudNC announces the release of Cutting Parameters AI, a new solution that automatically generates appropriate physics-based feeds and speeds for virtually any CNC machining scenario, in moments. . Defining new feeds and speeds for CNC machining operations is an arduous and time-consuming task, involving considerable manual experimentation . Similarly, in the aerospace industry, the F-15’s starter assemblies and rocket engine components rely on Inconel’s unique properties to function in environments that would spell doom for lesser materials. Machining Inconel, then, is about more than just shaping metal; it’s about forging the future. Essential Machining Parameters for Inconel

black blum stainless steel lunch box

These terms refer to two critical parameters in CNC machining that significantly impact the cutting process, tool life, and overall machining quality. Feeds vs Speeds Speeds refer to the rotational speed of the cutting tool or workpiece, typically measured in revolutions per minute (RPM), also known as spindle speed.Machining Parameters: Feed rate, cutting speed, and depth of cut must be optimized to minimize surface roughness. Lower feed rates and higher cutting speeds often result in better surface finishes. . Jones, R. (2021). "Determining Optimal Cutting Speeds for CNC Machining." CNC Machining Today. White, A. (2020). "Feed Rate Optimization for . 3. Machine Capabilities. Your CNC machine’s capabilities and limitations matter. Pay attention to: Spindle Speed Range: Ensure your machine can achieve the required cutting speeds. Adjust the spindle speed (rpm) based on the material and tool. Feed Rate Limits: Understand the maximum feed rate (vf) your machine can handle. Exceeding it may . Customized Copper CNC Machining Services. Customized copper CNC machining services open up a world of possibilities for creating copper components to meet specific client needs. Delivering consistent quality, fast turnaround times, and a wide variety of post-processing options, copper machining services are at the forefront of copper machining.

CNC machining PC (polycarbonate) is a popular manufacturing method for creating precision PC plastic parts. . that the machinability of polycarbonate may vary depending on the specific grade of material and the machining parameters used. For example, some grades of polycarbonate may be more brittle than others and may require different . Use long ratio pecks. Another trick I might do is not not back the drill out of the hole completely to keep from having the chips fall back in the hole. Slamming into chips on a peck will break down drills too. Maybe even increase the peck retract distance in the machine parameters if you're drilling a lot of harder materials.. The effects of machining parameters in milling operations such as spindle speed, depth of cut and feed rate are investigated in order to minimize the surface roughness as well as time of machining .

CNC (Computerized Numerical Control) machining is a subtractive manufacturing process that uses programmed code to control the movement of the tool axis. The programming code includes all necessary cutting parameters, such as cutting tool movement, spindle speed, feed rate, speed, etc. Therefore, engineers and machinists must understand cutting speeds .

cnc parameter settings

What is Sheet Metal Stamping? The technical definition of metal stamping is that it’s a type of cold forming process that uses extreme force and/or speed to permanently alter the shape of a piece of metal. For sheet metal stamping, the work piece is sheet metal.

cnc machining parameters throughput|cnc machining parameters list