welding nuts to sheet metal Steel Narrow-Base Weld Nuts with Projections. Projections on the base of these steel nuts concentrate your weld and create room for heat to dissipate, protecting threads from . Outdoor Junction Box,Nineleaf IP66 Weatherproof Electrical Project Boxes PVC/ABS Plastic Enclosure Box Universal Watertight 4.9 x 3.3 x 2.3 inch (125x86x62mm), Fit with 20mm Cable Gland Grey

0 · welding nuts in metal

1 · welding nuts for sale

2 · welding nuts

3 · welding nut replacement

4 · welding nut for fasteners

5 · stainless steel welding nuts

6 · aluminum weld nuts

7 · aluminum weld nut installation

The WEATHER GUARD Model 120-3-04 is a low profile steel truck tool box for full size trucks and is powder coated in a White ARMOR TUF® finish ensuring years of dependability.

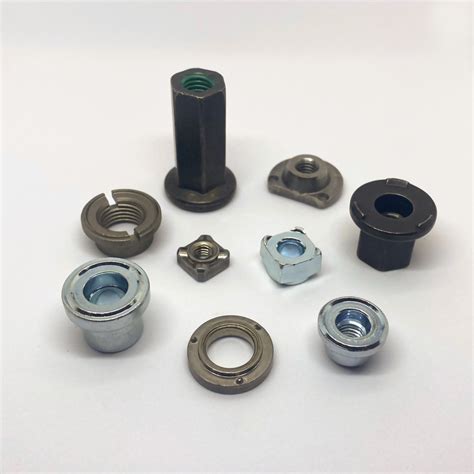

Steel Narrow-Base Weld Nuts with Projections. Projections on the base of these steel nuts concentrate your weld and create room for heat to dissipate, protecting threads from .Weld nuts are highly specialized fasteners that are designed to be welded to another metal object. There are numerous weld nut options to suit a wide range of applications. Some weld nut .The Most Common Sheet Metal Fastening Methods. Sheet metal can be used in almost any project. It can be applied using various methods, such as loose hardware application, welding and self clinching. Loose hardware can include .Weld fasteners provide a preferred materially binding solution for creating super-strong and permanent connections between steel sheet or tubing and fasteners. These unique fasteners feature durable threads with proven reliability, saving .

A weld nut is a type of nut that is specially designed to be welded to another workpiece. Different types of weld nuts are used for different purposes. These include round base nuts, slab base nuts, tab base nuts, hex and square .These weld nuts stand up to high torque and pull force better than rivet and press-fit nuts, making them the strongest way to add permanent threads to sheet metal. Made of plain steel, these .

PEM® weld nuts (Types WN/WNS) provide load-bearing threads in metal sheets too thin to tap, and permit faster assembly. PEM brand weld nuts overcome many problems associated with other weld nuts – burn-outs, complicated electrodes and pilots, tedious time-consuming indexing and re-tapping to remove weld spatter.M6 Hexagon Weld Nut in Steel Zinc & Clear Cr3 with dimensional measurements and 3D model, in a range of finishes [PRICE] | CAREERS. My account View enquiries View collections. Company. . Fasteners for Sheet Metal; Weld Nuts; Hexagon; TR00001235-100; M6 Hexagon Weld Nut Metric. For thin sheet metal welding it can be 30 ampere while for thicker (e.g. 1/8” square groove weld)- it can go up to 220 ampere for example. GMAW-S gives low heat and makes it easy to use in all positions on sheet metal, low .

Browse Nuts for Sheet Metal in the PennEngineering catalog including Floating Nuts – Types A4, AS, AC, LA4, LAC, LAS,Blind Nuts – Types B, BS,Nuts – Types CLA, CLS, CLSS, H, HNL, S, SS, SMPS, SP, SMPP,Nuts (all) for Installing into Stainless Steel – . Self-Clinching vs Weld ; What is Self-Clinching Technology? Download Catalog . When your sheet metal part needs threads, you may assume that weld nuts are the answer. While it’s true that rivet nuts require more clearance than weld nuts, they’re a low-cost alternative that benefits many applications. We also receive orders for sheet metal fabrication services with standard tapping callouts, but this option typically .

Irregularly shaped threads in these nuts form a tight grip, preventing screws from backing out in vibration-heavy environments. These weld nuts stand up to high torque and pull force better than rivet and press-fit nuts, making them the strongest way to add threads to sheet metal. They can be welded onto thick metal surfaces, too. To protect their threads from deforming, these nuts .There are a number of different types of weld-nut available commercially; some are covered by national standards such as British Standard BS 7670 'Steel nuts and bolts for resistance welding' (DIN equivalents). . although some types are formed from sheet metal with embossed projections within an integral flange. In each case, there are .Add permanent threads to sheet metal, like weld nuts, but without the setup and mess. A zinc plating on these steel press-fit nuts helps prevent rust in wet environments. Metric Steel Press-Fit Nuts for Sheet Metal. Add permanent metric threads to sheet metal, like weld nuts, but without the setup and mess.

Captive nuts are a fantastic solution for many assembly challenges, offering a simple, effective way to join metal parts without welding. By understanding the basics of how captive nuts work, designing with the right tolerances, and being mindful of material properties, you can achieve strong, reliable assemblies that are easy to put together . 5 ASM Is Your Go-To Partner for Welding and Riveting; 6 Sheet Metal Hardware Hole Sizes Chart. 6.1 CHART DOWNLOAD; 7 Welding vs. Riveting Sheet Metal Parts FAQ. 7.0.1 What's the primary difference between welding and riveting in sheet metal fabrication? 7.0.2 When should I choose welding over riveting for my sheet metal parts? Assembling Sheet Metal With Fasteners i.e. Nuts & Screws. You can use fasteners such as nuts and screws to directly hold onto sheet metal pieces. . Nut. 2. Welding Sheet Metal. We conduct welding sheet metal assembly by fusing two pieces to form a single product. Usually, we use welding sheet metal assembly when you need strong and permanent .

If you've ever tried to tap an M6 thread into a 1.5mm sheet metal part in real life, you will find that the threads strip very easily due to the fact that yo.In the extrude and tap process, the panel must first be punched in order to extrude the sheet metal which effectively thickens the sheet metal. Then a self-tapper screw is inserted. Self-Tapping vs. Self-Drilling. Is there a difference between self-drilling and self-tapping screws? The answer is yes, but the terms are often interchanged. If you’ve ever tried to tap an M6 thread into a 1.5mm sheet metal part in real life, you will find that the threads strip very easily due to the fact that you will not even get 2 full threads in the material. Clinch nuts are the ideal answer, but another commonly used practise is to simply weld a standard nut onto the sheet metal part.These Stainless Steel Weld Nuts (T-Nuts) offer excellent load distribution when fixed to thin sheet metal. Designed for applications where corrosion resistance is a priority, Weld Nuts are manufactured to the highest standard. • Excellent .

Irregularly shaped threads in these nuts form a tight grip, preventing screws from backing out in vibration-heavy environments. These weld nuts stand up to high torque and pull force better than rivet and press-fit nuts, making them the strongest way to add threads to sheet metal. They can be welded onto thick metal surfaces, too. To protect their threads from deforming, these nuts .

PEM® weld nuts (Types WN/WNS) provide load-bearing threads in metal sheets too thin to tap, and permit faster assembly. PEM brand weld nuts overcome many problems associated with other weld nuts – burn-outs, complicated electrodes .PEM® weld nuts (Types WN/WNS) provide load-bearing threads in metal sheets too thin to tap, and permit faster assembly. PEM brand weld nuts overcome many problems associated with other weld nuts – burn-outs, complicated electrodes and pilots, tedious time-consuming indexing and re-tapping to remove weld spatter.

Let us say we want to weld a nut in place against a piece of metal. The nut would then be used to receive a bolt to hold parts together. Do you position the nut by just placing it against the metal, or do you put the bolt in place with the threads only flush and weld, using the bolt to align the . The weld nut specimen used in the fatigue experiments enabled the investigation of how the fatigue characteristics of sheet metal are affected by single and double sheet weld nut bolt joint configurations, see Fig. 1.The single sheet specimen was manufactured as a circular plate with an outer diameter of 120 mm.A hole was punched and a nut was projection welded .A weld nut is a type of fastener designed to weld to another component in an assembly. Weld nuts can replace sheet metal screws in thin sheet metal applications. Once welded, they form a powerful bond. How Do Weld Nuts Work? There are two methods of installing weld nuts in metalwork: projection welding or capacitive discharge welding.

welding nuts in metal

A friend asked me to weld a 1 1/2" nut to a 4" x 4" x 3/8" mild steel plate. Any recommendations on how to weld it? My welder is an HH180 and I have E70S-6 in .030 and .035 with C25 gas. . for what its worth at work we usually use a nut or bolt of a different metal to prevent distortion. ie use a SS bolt in the nut as they will absorb heat at . To use a weld nut, first, you need to weld it onto the metal surface. Once the weld nut is welded, you can screw in a threaded stud. First, place the stud into the weld nut and hand-tighten it to ensure a secure connection. Then, use a wrench to tighten it further until it is snug. Conclusion: Weld nuts are essential in various manufacturing . You can attach a right-angled weld nut to the base metal to create a threaded hole, which should be aligned vertically to the surface. . This type of weld nut is ideal for heavy gauge sheet metals. It is also equally effective for curved surfaces. Hex 3 projection weld nuts.

These weld nuts stand up to high torque and pull force better than rivet and press-fit nuts, making them the strongest way to add permanent threads to flat sheet metal. Made of plain steel, they weld to uncoated steel with minimal preparation. You can also weld them onto thick metal surfaces. For technical drawings and 3-D models, click on a .

Also known as self-locating weld nuts, projection weld nuts provide load-bearing threads in sheets too thin to tap. These projection weld nuts have an increased torque value compared to other non-welded nuts and perform at a much higher level in most heavy-duty industrial applications, such as in automotive, aerospace, manufacturing, and more. As an ISO 9001:2015 certified .Welding is historically one of the most common sheet metal fastening methods. The welding technique is a fabrication process consisting of two or more parts fused through heat or pressure. . While self clinching and welding processes are effective ways of applying fasteners to sheet metal, self-clinching has various benefits that set it apart .

1 2 weatherproof cord grip connector for plastic electrical box

1 2 inch mounting lug for electrical box

Get free shipping on qualified Outdoor Weatherproof Boxes products or Buy Online Pick Up in Store today in the Electrical Department.

welding nuts to sheet metal|welding nuts for sale