working with aluminum sheet metal This complete guide’ll walk you through the basics of sheet metal fabrication and provide all the information you need to get started. From understanding the materials and processes involved to tips on finding the right . The first, and most common, and nearest to densely populated areas is a vent box. This is a round cast iron plumbing cover with louvers about 6″ in diameter. Typically, they are black but often get painted. They are flush with concrete or .

0 · aluminum sheet metal specifications

1 · aluminum sheet metal manufacturers

2 · aluminum sheet metal grades

3 · aluminum sheet metal forming

4 · aluminum sheet metal fabricators

5 · aluminum sheet metal fabrication process

6 · aluminum sheet metal bending

7 · aluminum sheet metal

The thickness of 18-gauge sheet metal is 0.0478 inches (1.214 mm) thick specifically as per the Manufacturer’s standard gauge steel sheet. The need for Ra-45 per ISO 1302 geometrical 4.6.4.3 standard enables the industrial applications of the seas efficaciously. Q: What is the advantage of using 18 gauge as opposed to 16 or 20 gauge sheet .One crucial element of CNC machines is the Z-axis, which plays a pivotal role in determining the vertical direction of the tool. In this blog post, we will explore the Z-axis direction in CNC machines, its significance, and how it affects the manufacturing process.

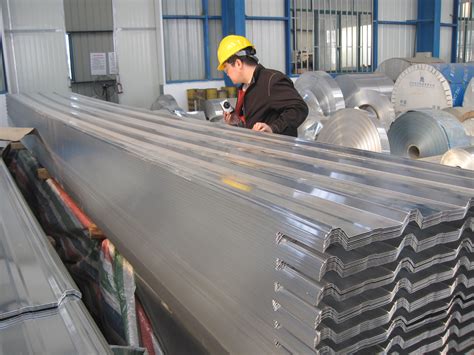

From left to right: Galvanized Steel, Brass, Steel, Copper, Aluminum. Thinking of building an enclosure for your latest project? Or maybe you’re working on a giant robot to terrorize the . The process of sheet metal fabrication entails shaping aluminum sheets into metal products of different shapes and sizes. Fabricators use .

This blog will provide technical tips and techniques to overcome these challenges. From choosing the right alloy to mastering advanced cutting and welding processes, we will .

new work metal electrical box

And aluminum has long been a staple material here at Approved Sheet Metal. Understanding this metal’s unique properties will help you . This complete guide’ll walk you through the basics of sheet metal fabrication and provide all the information you need to get started. From understanding the materials and processes involved to tips on finding the right . Working with aluminum sheet metal requires precise techniques and attention to detail. Many factors must be considered, from selecting the right material to using advanced cutting, welding, and forming techniques. Whether in aerospace, automotive, or any high-performance industry, mastering these tips will improve your fabrication results and . Working with aluminum sheet metal requires precise techniques and attention to detail. Many factors must be considered, from selecting the right material to using advanced cutting, welding, and forming techniques. Whether in aerospace, automotive, or any high-performance industry, mastering these tips will improve your fabrication results and .

Working with aluminum sheet metal requires precise techniques and attention to detail. Many factors must be considered, from selecting the right material to using advanced cutting, welding, and forming techniques. Whether .

aluminum sheet metal specifications

Working with aluminum sheet metal requires precise techniques and attention to detail. Many factors must be considered, from selecting the right material to using advanced cutting, welding, and forming techniques. Whether in aerospace, automotive, or any high-performance industry, mastering these tips will improve your fabrication results and . Working with aluminum sheet metal requires precise techniques and attention to detail. Many factors must be considered, from selecting the right material to using advanced cutting, welding, and forming techniques. Whether in aerospace, automotive, or any high-performance industry, mastering these tips will improve your fabrication results and .

Working with aluminum sheet metal requires precise techniques and attention to detail. Many factors must be considered, from selecting the right material to using advanced cutting, welding, and forming techniques. Whether in aerospace, automotive, or any high-performance industry, mastering these tips will improve your fabrication results and .One of the most important decisions when working with sheet metal is deciding what thickness you’ll need. Similar to wire, sheet metal thickness is measured in gauges, with a higher number indicating a thinner sheet. . It might sound crazy, but you can cut sheets of aluminum on a table saw. Make sure to use a 60-tooth (or more) carbide .

Working with aluminum sheet metal requires precise techniques and attention to detail. Many factors must be considered, from selecting the right material to using advanced cutting, welding, and forming techniques. Whether in aerospace, automotive, or any high-performance industry, mastering these tips will improve your fabrication results and .

Working with aluminum sheet metal requires precise techniques and attention to detail. Many factors must be considered, from selecting the right material to using advanced cutting, welding, and forming techniques. Whether in aerospace, automotive, or any high-performance industry, mastering these tips will improve your fabrication results and . Working with aluminum sheet metal requires precise techniques and attention to detail. Many factors must be considered, from selecting the right material to using advanced cutting, welding, and forming techniques. Whether in aerospace, automotive, or any high-performance industry, mastering these tips will improve your fabrication results and .

Working with aluminum sheet metal requires precise techniques and attention to detail. Many factors must be considered, from selecting the right material to using advanced cutting, welding, and forming techniques. Whether in aerospace, automotive, or any high-performance industry, mastering these tips will improve your fabrication results and .

Working with aluminum sheet metal requires precise techniques and attention to detail. Many factors must be considered, from selecting the right material to using advanced cutting, welding, and forming techniques. Whether in aerospace, automotive, or any high-performance industry, mastering these tips will improve your fabrication results and . Working with aluminum sheet metal requires precise techniques and attention to detail. Many factors must be considered, from selecting the right material to using advanced cutting, welding, and forming techniques. Whether in aerospace, automotive, or any high-performance industry, mastering these tips will improve your fabrication results and . Working with aluminum sheet metal requires precise techniques and attention to detail. Many factors must be considered, from selecting the right material to using advanced cutting, welding, and forming techniques. Whether in aerospace, automotive, or any high-performance industry, mastering these tips will improve your fabrication results and .

The sheet metal manufacturing process begins with a large coil of metal fed into the sheet metal working machinery. The metal can be cut, stamped, or bent into the desired shape. Once the sheet metal has been . Working with aluminum sheet metal requires precise techniques and attention to detail. Many factors must be considered, from selecting the right material to using advanced cutting, welding, and forming techniques. Whether in aerospace, automotive, or any high-performance industry, mastering these tips will improve your fabrication results and .

nibbling tool for sheet metal

Working with aluminum sheet metal requires precise techniques and attention to detail. Many factors must be considered, from selecting the right material to using advanced cutting, welding, and forming techniques. Whether in aerospace, automotive, or any high-performance industry, mastering these tips will improve your fabrication results and . When buying and working with aluminum sheet metal, it is normal for the expression “gauge” to be used. If you are new to the gauge framework may not comprehend what is implied by 18 gauge steel, for instance. So, what is aluminum sheet metal gauge? Gauges, in most cases, are used for expressing the thickness of aluminum sheet metal. Laser and water jet cutting are the most popular techniques for working with aluminum sheet metal. Laser cutting is fast and precise, but the heat generated can cause thermal expansion, distorting the sheet. Water jet cutting uses high-pressure water mixed with an abrasive, which avoids heat-related issues and is better for thicker aluminum sheets. Working with aluminum sheet metal requires precise techniques and attention to detail. Many factors must be considered, from selecting the right material to using advanced cutting, welding, and forming techniques. Whether in aerospace, automotive, or any high-performance industry, mastering these tips will improve your fabrication results and .

Working with aluminum sheet metal requires precise techniques and attention to detail. Many factors must be considered, from selecting the right material to using advanced cutting, welding, and forming techniques. Whether in aerospace, automotive, or any high-performance industry, mastering these tips will improve your fabrication results and . Working with aluminum sheet metal requires precise techniques and attention to detail. Many factors must be considered, from selecting the right material to using advanced cutting, welding, and forming techniques. Whether in aerospace, automotive, or any high-performance industry, mastering these tips will improve your fabrication results and .

aluminum sheet metal manufacturers

aluminum sheet metal grades

Working with aluminum sheet metal requires precise techniques and attention to detail. Many factors must be considered, from selecting the right material to using advanced cutting, welding, and forming techniques. Whether in aerospace, automotive, or any high-performance industry, mastering these tips will improve your fabrication results and . Working with aluminum sheet metal requires precise techniques and attention to detail. Many factors must be considered, from selecting the right material to using advanced cutting, welding, and forming techniques. Whether in aerospace, automotive, or any high-performance industry, mastering these tips will improve your fabrication results and . Working with aluminum sheet metal requires precise techniques and attention to detail. Many factors must be considered, from selecting the right material to using advanced cutting, welding, and forming techniques. Whether in aerospace, automotive, or any high-performance industry, mastering these tips will improve your fabrication results and .

new stainless steel work bench tool cabinet

aluminum sheet metal forming

What Is The Electrical Box In A House Called? It’s commonly referred to as the service panel, junction box, or breaker box. This box serves as the main distribution point for electrical circuits in your home.

working with aluminum sheet metal|aluminum sheet metal