cnc machining benefits For small firms and startups, traditional machining technologies can be expensive and time-consuming. However, CNC prototype machining offers businesses or manufacturing companies that want to produce parts and components a quick, cost-effective way that maintains precision and quality. One major reason why CNC prototype machining is becoming the first . Originally built in 1999 as the pioneering tiny house RV, this classic design remains .

0 · pros and cons of machining

1 · disadvantages of cnc milling

2 · disadvantages of cnc

3 · cnc milling pros and cons

4 · cnc milling advantages and disadvantages

5 · cnc machining advantages and disadvantages

6 · cnc machine pros and cons

7 · cnc advantages and disadvantages

CNC turning is a subtractive manufacturing process that uses computer-controlled machines to remove material from a workpiece. This process is commonly used to create cylindrical parts, such as shafts, rods, and bearings.

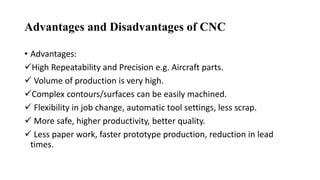

CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique . For small firms and startups, traditional machining technologies can be expensive and time-consuming. However, CNC prototype machining offers businesses or manufacturing companies that want to produce parts and components a quick, cost-effective way that maintains precision and quality. One major reason why CNC prototype machining is becoming the first . 10 Benefits of CNC Machining 1. CNC Machining Reduces Material Wastage On Floor. CNC machining is an effective process in terms of minimizing wasted material. When designing parts, the faulty cuts are likely to be minimal. Accuracy leads to less likelihood of having several faulty products, therefore optimizing the material usage. CNC machining enhances manufacturing efficiency, precision, and cost-effectiveness across industries like automotive, aerospace, medical, electronics, and construction. Its key benefits include high accuracy, repeatability, flexibility, reduced labor costs, and material versatility, making it essential for producing complex, high-quality components.

CNC machining is important to handle the increasing demand for high-quality precision machined parts and prototyping in the medical industry. These CNC machined medical equipment and instruments must be on-demand manufacturing and meet the industry’s standards. Therefore, product teams and manufacturers rely on CNC machining to meet quality standards .The Benefits of CNC Machining for In-Demand Industries. Industry leaders view CNC machining as a vital aspect of the modern economy. Various processes create critical components of our everyday lives. Imagine an airport without airplanes or a highway without cars. That’s how the world would look without precision machining.

Benefits of CNC machining. Highly accurate parts with tight tolerances. CNC machining can create parts with greater dimensional accuracy than most other common manufacturing technologies. During the final finishing machining steps, material can be removed from the workpiece very accurately, achieving very tight tolerances. . CNC machining is very useful in the following areas: Rapid Prototyping. CNC machines have fast turnarounds because they are highly autonomous. Once a digital design is complete, machinists can send them to the CNC machine and fabricate them in a short space of time. This makes CNC machining highly useful for prototype machining. The application . Due to automation, lack of human error, and the ability of machines to run 24/7, there are many CNC machining benefits. What is CNC Machining? CNC machining is a manufacturing process that utilizes a programmed computer to create parts with precision. To begin, numerical software is uploaded into the machine, and the computerized controls and . Benefits of Integrating CNC Machining in PCB Fabrication. Enhanced Precision. CNC machining provides unmatched accuracy, with tolerances often as tight as ±0.01 mm. This precision is critical in PCB fabrication, where small errors can lead to significant performance issues or failures. Increased Efficiency

Unveiling the Hidden Gems: Exploring the Unknown Benefits of 5-Axis Machining. March 26, 2024. Read More. Unveiling the Power of 5-Axis CNC Machining: Key Benefits and Advantages. February 29, 2024. Read More. Unveiling the Speed Titan: Brother U500xd1 5-Axis CNC Machine Tool. February 16, 2024. Read More CNC machining has gained popularity in the automotive sector in recent years due to its numerous benefits. The following are some benefits of CNC machining in the automotive industry. High Repeatability. CNC Machining in automotive industry guarantees repeatability because it is a computer-controlled process. Machine Wear and Maintenance: High-volume and precision machining can lead to rapid wear and tear of CNC machines, necessitating frequent maintenance, which can disrupt production schedules. Regulatory Compliance : The energy sector is highly regulated, and complying with international and local standards can complicate the manufacturing . Benefits of Stainless Steel for CNC Machining. Stainless steel is a commonly used CNC Machining material across industries. Here are some of the benefits of using stainless steel for your CNC machining projects. Corrosion Resistance. Stainless steel is naturally corrosion-resistant. Hence, stainless steel machined parts can withstand rust and .

High-speed CNC machining has many benefits over traditional machining methods. The higher speed and feed rate employed in HSM result in rapid cutting, minimal heat transfer and decreased shop emissions, along with numerous other advantages. These are the main benefits of rapid CNC machining: 1. Extends Equipment Life Span

pros and cons of machining

disadvantages of cnc milling

CNC machining has gained popularity in the automotive sector in recent years due to its numerous benefits. The following are some benefits of CNC machining in the automotive industry. High Repeatability. CNC Machining in the automotive industry guarantees repeatability because it is a computer-controlled process. Additionally, CNC machining’s speed and accuracy in the development cycle of consumer products and electronics enable manufacturers to keep up with market trends. Advantages and Challenges of CNC Machining .

When it comes to plastic machining, Nylon can be easily machined using CNC (Computer Numerical Control) techniques. CNC machining offers precise control over the cutting tools, allowing for intricate designs and .

5-Axis CNC Machining has emerged as a game-changing technology in modern manufacturing, revolutionizing industries that demand high precision, flexibility, . 5-Axis CNC Machining Explained: Benefits and Use Cases 2024 .Benefits of CNC Precision Machining Service. CNC precision machining services play a pivotal role in contemporary manufacturing, providing an array of advantages, including exceptional accuracy, adaptability with a variety of materials, and expertise in shaping intricate forms. The automated essence of CNC machining ensures streamlined . Benefits Of CNC Machining. CNC machining is outstanding for several reasons: 1. They’re More Accurate, Producing Minimal Defect. Ditch the manual woodwork since you’ll still see measurement inaccuracies even if you have accumulated years into this. Instead, choose CNC machines that can receive accurate computer instructions to provide .

What is CNC Machining? CNC machining is a manufacturing process that uses computer-controlled machines to create precise parts. It stands for "Computer Numerical Control." How CNC Machining Works . CNC machines operate using pre-programmed software and code. This code controls the movement of cutting tools, such as drills and lathes. The . In today’s competitive manufacturing landscape, precision and efficiency are paramount. Companies seeking to optimize their production processes often turn to CNC machining services. While some choose to keep these operations in-house, an increasing number of businesses are realizing the advantages of outsourcing CNC machining. Here are the benefits of outsourcing CNC machining: Better Precision. One of the most important benefits of CNC machining outsourcing is the improved precision of the machined parts. Due to their full concentration on CNC machining, these shops, which offer the service, have a higher quality output than an integrated company using traditional .

As evident from the above benefits, CNC technology brings a multitude of advantages to manufacturers, ranging from cost reduction and waste reduction to improved worker safety and operational intelligence. The integration of CNC technology empowers businesses to thrive in today’s competitive manufacturing landscape. . CNC machining plays . There are no trade-offs with a CNC machine. Such benefits, together with the ability to maintain a high degree of accuracy and minimal waste of material resources, make CNC machining and milling one of the best ways to ensure production is efficient, fast, and scalable with a lower cost liability. Precision CNC machining has several benefits. Let’s explore some core ones; Precision and Accuracy. CNC machining can be described as a process that is defined by the capacity to achieve high precision in the working process because of the control of the tool and the operation of the machine.

CNC Machining Parts: Definition, Benefits, and Design Guide. In today’s world, lathe machined parts are everywhere and it’s easy to see why, mainly because turned parts manufacturers are constantly improving their machining technology. They are an integral part of most machinery as they offer precision and efficiency in an affordable manner.

disadvantages of cnc

fresno metal fabrication

To convert an existing metal building for use as residential space the steps to take are. 1) Check for proper zoning; 2) Get a building permit if necessary, and; 3) Create a renovation plan. Zoning: Zoning rules govern the use of properties located in certain areas.

cnc machining benefits|cnc machine pros and cons