cnc machine ka program Computer-Aided Design (CAD) software for CNC (Computer Numerical Control) machines is a type of program that helps engineers and designers create precise 3D models of parts and . A welded box steel column is a structural member that is made by welding together four pieces of steel plate to form a box-shaped cross-section. The web and flanges of the column are typically made of the same material and thickness.

0 · cnc software for manufacturing

1 · cnc programming process

2 · cnc machining software

3 · cnc machining cam software

4 · autodesk cnc training

5 · autodesk cnc software download

6 · autocad cnc training

7 · autocad cnc software download

Founded in 1990 and headquartered in a 30,000 square foot facility west of Denver in Arvada, Colorado, Weiser is an industry leader in precision sheet metal fabrication, high-value machining, and assembly and welding services—serving their .

Computer-Aided Design (CAD) software for CNC (Computer Numerical Control) machines is a type of program that helps engineers and designers create precise 3D models of parts and .Speed up 2D, 2.5D, 3-, 4- and 5-axis CAM programming with automation and user .Autodesk Fusion is next-generation, integrated CAD/CAM software that .Speed up 2D, 2.5D, 3-, 4- and 5-axis CAM programming with automation and user-defined templates built around your best practices. Make better use of your 4- and 5-axis CNC machines. Produce high-quality parts using fewer setups .

What is CNC Software? “CNC programming software (Computer Numerical Control Software) is software that allows mobile devices such as a computer to communicate with .Autodesk Fusion is next-generation, integrated CAD/CAM software that provides a comprehensive suite of strategies to automate the programming and CNC machining of complex, feature-rich parts. With Fusion, you can: Program your .

CNC programming is the process of creating a set of coded instructions, called a CNC machining program, that controls the operation of a CNC machine. These instructions are input into the CNC system and guide .The three different programming methods for CNC machines are manual, computer-aided manufacturing (CAM) and conversational programming. Which one you use depends on the machine type, your skills and the output .

cnc software for manufacturing

CNC programming involves you or a fellow colleague using computer-aided manufacturing (CAM) software to convert a CAD file into a language that a CNC machine can read, whether it’s a cutting, milling, or .Understanding the basics of CNC programming, including G-code language, CAD/CAM software, and the key steps involved, empowers manufacturers and programmers to unlock the full potential of CNC machines. CNC Machine Components: Explore the key components of CNC machines and their functions, from the controller to the cutting tools. G-code and M-code: Grasp the essential .

Computer-Aided Design (CAD) software for CNC (Computer Numerical Control) machines is a type of program that helps engineers and designers create precise 3D models of parts and assemblies to be produced on a CNC machine.

Speed up 2D, 2.5D, 3-, 4- and 5-axis CAM programming with automation and user-defined templates built around your best practices. Make better use of your 4- and 5-axis CNC machines. Produce high-quality parts using fewer setups which lowers production costs. Dedicated 2D turning strategies. What is CNC Software? “CNC programming software (Computer Numerical Control Software) is software that allows mobile devices such as a computer to communicate with CNC machine tools like lathes, saws, plasma cutters, mills, etc.” Rather than having a human operator perform each task, CNC software essentially assists in the cutting and shaping. Here’s how to program a CNC Machine: 1. Choose a CAD/CAM Software: a. CAD Model Creation: Use Computer-Aided Design (CAD) software to create a 3D model of your part. It’s like shaping things digitally, turning your ideas into a .Autodesk Fusion is next-generation, integrated CAD/CAM software that provides a comprehensive suite of strategies to automate the programming and CNC machining of complex, feature-rich parts. With Fusion, you can: Program your parts with ease; Create high-quality NC code for 2D, 3-, 4- and 5-axis machines

CNC programming is the process of creating a set of coded instructions, called a CNC machining program, that controls the operation of a CNC machine. These instructions are input into the CNC system and guide the machine’s movements to produce a desired part.The three different programming methods for CNC machines are manual, computer-aided manufacturing (CAM) and conversational programming. Which one you use depends on the machine type, your skills and the output requirements. CNC programming involves you or a fellow colleague using computer-aided manufacturing (CAM) software to convert a CAD file into a language that a CNC machine can read, whether it’s a cutting, milling, or turning tool (although they can also be programmed manually). Here’s an example of a CNC programming console:

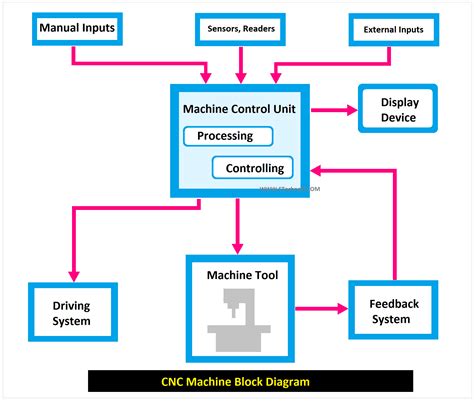

Understanding the basics of CNC programming, including G-code language, CAD/CAM software, and the key steps involved, empowers manufacturers and programmers to unlock the full potential of CNC machines. CNC Machine Components: Explore the key components of CNC machines and their functions, from the controller to the cutting tools. G-code and M-code: Grasp the essential programming languages used in CNC machining. Learn how to write and understand G-codes for positioning and M-codes for machine functions.Computer-Aided Design (CAD) software for CNC (Computer Numerical Control) machines is a type of program that helps engineers and designers create precise 3D models of parts and assemblies to be produced on a CNC machine.

Speed up 2D, 2.5D, 3-, 4- and 5-axis CAM programming with automation and user-defined templates built around your best practices. Make better use of your 4- and 5-axis CNC machines. Produce high-quality parts using fewer setups which lowers production costs. Dedicated 2D turning strategies.

What is CNC Software? “CNC programming software (Computer Numerical Control Software) is software that allows mobile devices such as a computer to communicate with CNC machine tools like lathes, saws, plasma cutters, mills, etc.” Rather than having a human operator perform each task, CNC software essentially assists in the cutting and shaping.

Here’s how to program a CNC Machine: 1. Choose a CAD/CAM Software: a. CAD Model Creation: Use Computer-Aided Design (CAD) software to create a 3D model of your part. It’s like shaping things digitally, turning your ideas into a .Autodesk Fusion is next-generation, integrated CAD/CAM software that provides a comprehensive suite of strategies to automate the programming and CNC machining of complex, feature-rich parts. With Fusion, you can: Program your parts with ease; Create high-quality NC code for 2D, 3-, 4- and 5-axis machines CNC programming is the process of creating a set of coded instructions, called a CNC machining program, that controls the operation of a CNC machine. These instructions are input into the CNC system and guide the machine’s movements to produce a desired part.

The three different programming methods for CNC machines are manual, computer-aided manufacturing (CAM) and conversational programming. Which one you use depends on the machine type, your skills and the output requirements. CNC programming involves you or a fellow colleague using computer-aided manufacturing (CAM) software to convert a CAD file into a language that a CNC machine can read, whether it’s a cutting, milling, or turning tool (although they can also be programmed manually). Here’s an example of a CNC programming console:

cnc programming process

Understanding the basics of CNC programming, including G-code language, CAD/CAM software, and the key steps involved, empowers manufacturers and programmers to unlock the full potential of CNC machines.

metal building house conversion

cnc machining software

That’s why we have put together a comprehensive guide on how to weld sheet metal on cars so you can confidently tackle any project. In this blog post, we’ll walk through all the steps necessary to start picking up welding yourself and applying it .

cnc machine ka program|autodesk cnc software download