all sheet metal processes The family of manufacturing processes used to create sheet metal components encompasses a diverse range of techniques, each tailored to achieve specific shapes, sizes, and features with precision and efficiency. 1,204 Welder Metal Fabricator jobs available on Indeed.com. Apply to Metal Fabricator, Fabricator/welder, Structural Welder and more!

0 · various sheet metal processes

1 · types of sheet metal process

2 · sheet metal working process pdf

3 · sheet metal processes pdf

4 · sheet metal process in manufacturing

5 · sheet metal operations with diagrams

6 · sheet metal forming process pdf

7 · sheet metal fabrication pdf

Find Champ Pans Weld-On Battery Boxes and get Free Shipping on Orders Over $109 at Summit Racing! Champ Pans weld-on battery boxes are made from steel and are lightweight, yet strong. They're available with or without mounting ears. Secure your battery with a stylish foundation; order the weld-on battery box best suited for your engine bay.

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different .

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly .

Sheet metal processing is a vast concept, covering several machining operations done to metal sheets. Since the topic is too broad, most people think the overall process only boils down to a single function. However, . Uncover the secrets of sheet metal: materials, geometries, and processes. Explore the world of stainless steel, carbon steel, and aluminum.The family of manufacturing processes used to create sheet metal components encompasses a diverse range of techniques, each tailored to achieve specific shapes, sizes, and features with precision and efficiency.Sheet metal processing, in essence, is an umbrella term encapsulating a wide array of techniques employed to manipulate and transform flat sheets of various metals into specific shapes and forms. Why Sheet Metal Processing is .

various sheet metal processes

The art and science of sheet metal fabrication involve a series of meticulous processes, from designing and cutting to bending and welding. This article unpacks the top ten technological processes, guiding you through each .

In this article we will discuss about the sheet metal manufacturing process and its operation types. Most of the sheet metal work is done on presses where a die and punch or other formed tools . Sheet metal fabrication is the process of transforming sheet metal (< 1/4” thick) into finished products, structures, and components. From household appliances to transportation, .

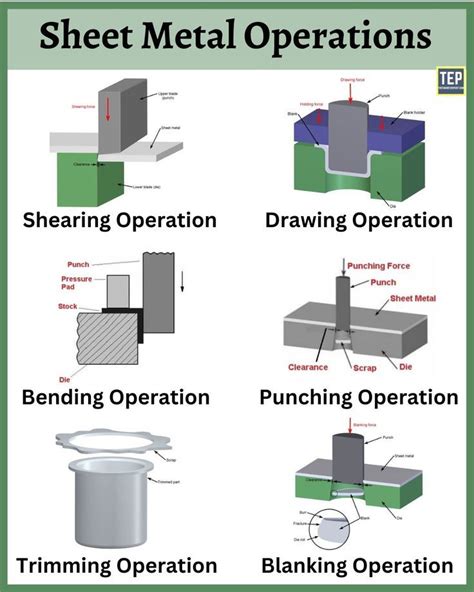

In this article, you will learn the 9 different types of sheet metal operations with diagrams. Also, you can download the pdf file of this post. What is the Sheet Metal Process? The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different processes and equipment, which we’ll cover a .

types of sheet metal process

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques.

Sheet metal processing is a vast concept, covering several machining operations done to metal sheets. Since the topic is too broad, most people think the overall process only boils down to a single function. However, there are two categories of . Uncover the secrets of sheet metal: materials, geometries, and processes. Explore the world of stainless steel, carbon steel, and aluminum.The family of manufacturing processes used to create sheet metal components encompasses a diverse range of techniques, each tailored to achieve specific shapes, sizes, and features with precision and efficiency.Sheet metal processing, in essence, is an umbrella term encapsulating a wide array of techniques employed to manipulate and transform flat sheets of various metals into specific shapes and forms. Why Sheet Metal Processing is Important?

sheet metal working process pdf

The art and science of sheet metal fabrication involve a series of meticulous processes, from designing and cutting to bending and welding. This article unpacks the top ten technological processes, guiding you through each step .In this article we will discuss about the sheet metal manufacturing process and its operation types. Most of the sheet metal work is done on presses where a die and punch or other formed tools are required. In press work large force is applied on thin sheet metals to give the required shape or to cut it in to the desired shape.

Sheet metal fabrication is the process of transforming sheet metal (< 1/4” thick) into finished products, structures, and components. From household appliances to transportation, commercial equipment to construction, sheet metal fabrication is critical to modern manufacturing. In this article, you will learn the 9 different types of sheet metal operations with diagrams. Also, you can download the pdf file of this post. What is the Sheet Metal Process? The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication.

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different processes and equipment, which we’ll cover a .

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques. Sheet metal processing is a vast concept, covering several machining operations done to metal sheets. Since the topic is too broad, most people think the overall process only boils down to a single function. However, there are two categories of . Uncover the secrets of sheet metal: materials, geometries, and processes. Explore the world of stainless steel, carbon steel, and aluminum.The family of manufacturing processes used to create sheet metal components encompasses a diverse range of techniques, each tailored to achieve specific shapes, sizes, and features with precision and efficiency.

Sheet metal processing, in essence, is an umbrella term encapsulating a wide array of techniques employed to manipulate and transform flat sheets of various metals into specific shapes and forms. Why Sheet Metal Processing is Important? The art and science of sheet metal fabrication involve a series of meticulous processes, from designing and cutting to bending and welding. This article unpacks the top ten technological processes, guiding you through each step .In this article we will discuss about the sheet metal manufacturing process and its operation types. Most of the sheet metal work is done on presses where a die and punch or other formed tools are required. In press work large force is applied on thin sheet metals to give the required shape or to cut it in to the desired shape.

sheet metal processes pdf

sheet metal process in manufacturing

sheet metal operations with diagrams

That is why we made this list of best welding projects for beginners and professionals that can give you some great ideas on how to improve your workshop, yard, decorate home, or just sell. Best Welding Projects for Your Workshop

all sheet metal processes|types of sheet metal process