5-axis cnc machining parts for automotive 5 axis CNC machining uses a machine that can simultaneously move and rotate in five axes to machine a part. Its benefits include its high suitability for fabricating parts with complex designs and intricate details, .

Tools: New and gently used hand and power tools can also be found in great .

0 · what is 5 axis milling

1 · what does 5 axis mean

2 · small 5 axis cnc mill

3 · benefits of 5 axis machining

4 · 5 axis trunnion machining

5 · 5 axis machining explained

6 · 5 axis machining basics

7 · 5 axis cnc explained

This part is a block, engine wiring harness junction (used with and without c60) (will accept 5-terminal fog lamp relay 12077866), for Chevrolet Trucks, Cadillac Trucks, and GMC Trucks cars. It fits for 219 General Motors vehicles which were sold in the U.S. from 1999 to 2002.

what is 5 axis milling

Miller CNC was founded by “motorheads,” so we understand that automotive machined parts need to not only conform to stringent engineering standards, but also adhere to strict aesthetic standards. We leverage our 3-axis and 5-axis machining capabilities with years of expertise and . See moreWe can procure material for your component, manufacture it to your specifications, and assemble the component as required. Automotive parts that benefit . See moreOur precision CNC machining and turning capabilities include in-house, full-service ISO 9001:2015 and AS9001 REV D-certified, ITAR-registered . See more

With immeasurable experience working with superalloys and hard-to-machine metals, our automotive machined parts expertise includes working with the . See more

what does 5 axis mean

small 5 axis cnc mill

With our roots deeply embedded in the automotive industry, we have created systems around part handling, automated deburring/surface finishing, non . See more 5 axis CNC machining uses a machine that can simultaneously move and rotate in five axes to machine a part. Its benefits include its high suitability for fabricating parts with complex designs and intricate details, .We leverage our 3-axis and 5-axis machining capabilities with years of expertise and ISO9001:2015 and AS9100-certified manufacturing process to create the highest-quality automotive parts on the market. For more information about our innovative CNC machining processes for the automotive industry, contact us or submit an RFQ online!

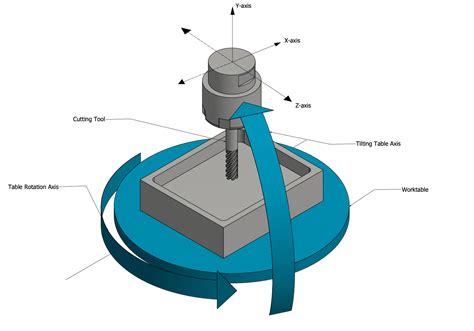

5 axis CNC machining uses a machine that can simultaneously move and rotate in five axes to machine a part. Its benefits include its high suitability for fabricating parts with complex designs and intricate details, accuracy, speed, and production efficiency.

Discover the benefits of 5-axis CNC machining in precision manufacturing. From enhanced accuracy to faster production and optimized tooling, learn how 5-axis technology is transforming aerospace, medical, and automotive industries with complex geometries and high-quality finishes. Explore why investing in 5-axis machines could elevate your manufacturing .Elimold manufactures custom automotive parts for Vehicle Engine Structure, Engine Valve And Connecting Rod Crank, cars, motorcycles, Engine Fuel Supply System and more. Using processes such as 3 axis, 4 axis, 5 axis, cnc turning machine, we make parts for car applications.5-axis machining provides unmatched precision and flexibility, enabling manufacturers to create intricate parts with fewer setups. This reduces the need for manual intervention, maintains tighter tolerances, and produces high-quality surface finishes, critical for industries like aerospace, automotive, and medical.

A 5-axis machine can easily approach the element closely from every angle in a single operation. It also reduces the need to reposition the workpiece between processes manually. In addition to saving time, 5-axis CNC machining is the best method for producing complex and accurate parts for major industries such as aerospace, oil and gas, and . In specific terms, we happen to use 5-axis CNC machining in creating carburetor housing and suspension parts. In addition, it finds a key role in accurately making bearing caps as well as engine casings. We achieve this using state-of-the-art tools and machines. For the more aesthetic auto parts, we carry out acrylic precision machining.

external electric meter box screwfix

With multi-axis manufacturing, complex geometries can be manufactured with ease via different axis manufacturing with a single machine. 5-Axis CNC automotive machining allows for the machine to remain tangent to the workpiece and then cut in multiple axes rapidly.

We will explain what 5-axis machining is, detail how the process operates, and break down the functions of the different axes. Additionally, you will learn about the advantages and disadvantages of utilizing this machining technique, as well as its common applications. On the other hand, 5 axis machining adds two additional rotational axes (A and B or C) to the traditional 3 axis CNC capabilities. This improvement allows the cutting tool to come at the workpiece from various angles, making it possible to machine complex parts with one setup.We leverage our 3-axis and 5-axis machining capabilities with years of expertise and ISO9001:2015 and AS9100-certified manufacturing process to create the highest-quality automotive parts on the market. For more information about our innovative CNC machining processes for the automotive industry, contact us or submit an RFQ online! 5 axis CNC machining uses a machine that can simultaneously move and rotate in five axes to machine a part. Its benefits include its high suitability for fabricating parts with complex designs and intricate details, accuracy, speed, and production efficiency.

Discover the benefits of 5-axis CNC machining in precision manufacturing. From enhanced accuracy to faster production and optimized tooling, learn how 5-axis technology is transforming aerospace, medical, and automotive industries with complex geometries and high-quality finishes. Explore why investing in 5-axis machines could elevate your manufacturing .Elimold manufactures custom automotive parts for Vehicle Engine Structure, Engine Valve And Connecting Rod Crank, cars, motorcycles, Engine Fuel Supply System and more. Using processes such as 3 axis, 4 axis, 5 axis, cnc turning machine, we make parts for car applications.

5-axis machining provides unmatched precision and flexibility, enabling manufacturers to create intricate parts with fewer setups. This reduces the need for manual intervention, maintains tighter tolerances, and produces high-quality surface finishes, critical for industries like aerospace, automotive, and medical.A 5-axis machine can easily approach the element closely from every angle in a single operation. It also reduces the need to reposition the workpiece between processes manually. In addition to saving time, 5-axis CNC machining is the best method for producing complex and accurate parts for major industries such as aerospace, oil and gas, and . In specific terms, we happen to use 5-axis CNC machining in creating carburetor housing and suspension parts. In addition, it finds a key role in accurately making bearing caps as well as engine casings. We achieve this using state-of-the-art tools and machines. For the more aesthetic auto parts, we carry out acrylic precision machining.

With multi-axis manufacturing, complex geometries can be manufactured with ease via different axis manufacturing with a single machine. 5-Axis CNC automotive machining allows for the machine to remain tangent to the workpiece and then cut in multiple axes rapidly.

We will explain what 5-axis machining is, detail how the process operates, and break down the functions of the different axes. Additionally, you will learn about the advantages and disadvantages of utilizing this machining technique, as well as its common applications.

benefits of 5 axis machining

Explore our auto body panels. Our restoration panels fit all makes and models, such as Chevrolet, GMC, Dodge, Ford, Honda, Toyota, Volkswagen, and more!

5-axis cnc machining parts for automotive|5 axis cnc explained