cnc machine dangers CNC machines themselves pose numerous hazards due to the amount of moving parts, size, high-speed movements, and sharp tools in the equipment. Fortunately, there are solutions and ways to mitigate the risks so .

$8.95

0 · The Three Types of Safety Hazards in CNC Machine

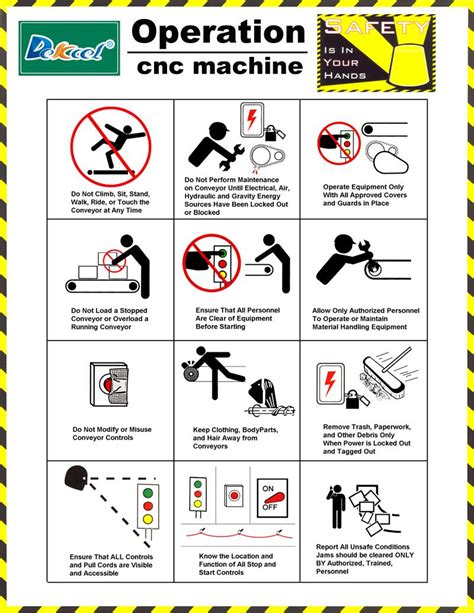

1 · Safety tips for CNC machinery operation

2 · Safety and Environmental Issues of CNC Machining

3 · Safety Tips for CNC Machinists: 5 Must

4 · MILLING MACHINES AND CNC MILLS: Safety Precautions

5 · Is CNC Machining Dangerous?

6 · Getting CNC machine safety right

7 · Five Safety Considerations for CNC Machinists

8 · CNC turning machine

9 · CNC Machine Safety: Preventing Accidents in the

This collection of products also includes junction boxes which include pull boxes, as well as indoor/outdoor junction boxes. Wire guard system products also include fittings such as elbows and coupling, where the latter helps to connect pieces of conduit.

Cutting tools can be very expensive, and operators know that if they use a cheaper tool they can save a little money, Quarato says. But CNC user manuals warn against altering the tooling or working outside the programmatic functions of the machine, he notes, and with good reason. “Alterations of any kind can cause . See more

Most employers know that having a clean machine will not only protect and extend the life of the machine, but also produce higher-quality parts. At the same time, housekeeping and total clean machine policies are mandatory for safe operations of CNC machines, . See moreIn addition to specific safety training for CNC machines, employers are required to provide equipment and training to meet The OSHA standard for noise protection and other personal . See moreAside from the fact that they are powerful enough to cut solid metal, CNC machines are dangerous in the sense that their surfaces can . See more

Learn about the potential hazards of CNC machines, their safety features, and guidelines that will enable you to safely work with these machines, preventing accidents in the workplace. 1. Noise. 2. Chips. 3. Moving . CNC machines themselves pose numerous hazards due to the amount of moving parts, size, high-speed movements, and sharp tools in the equipment. Fortunately, there are solutions and ways to mitigate the risks so . Spinning parts and tools may seem dangerous and they actually are, if not careful enough. But is the job of a CNC machine operator dangerous? Firstly, machining operations may emit quite a bit of dust and smoke. The dust . Two primary hazards arise from CNC turning operations: Entanglement and the ejection of parts. Se-rious lacerations, fractures, amputations, or even death can occur if an .

Safety in CNC environments is essential for users – and for productivity. Consider these 5 points to avoid injury, part failure and downtime. The most dangerous time for a CNC user is when a cutting tool approaches .Milling machines and computer-numerical-controlled (CNC) mills use moving cutters and/or move stock materials to cut shapes in materials such as metal, wood or plastic. Follow safety . CNC technology has been a boon for the machining industry and has made working with machines safer for operators, but there are still many dangers in using these modern .

One of the main safety issues of CNC machining is the potential for machine hazards, such as moving parts, sharp edges, hot surfaces, sparks, chips, and noise. These hazards can. Vertical machining center hazards. When operating a CNC vertical machine, machinists must be aware of the dangers it poses if not handled correctly and with appropriate supervision. Some of the common . CNC machining is dangerous, even for the most experienced metalworking professionals. That’s why safety managers and industrial hygienists should fully understand the nuances of CNC machine operations and the appropriate safety precautions to . Learn about the potential hazards of CNC machines, their safety features, and guidelines that will enable you to safely work with these machines, preventing accidents in the workplace. 1. Noise. 2. Chips. 3. Moving Components or Machinery. 4. Falling Heavy Objects. 5. Heat from the Cutting Process. 1. Safety or Containment Shield. 2. Video Cameras.

CNC machines themselves pose numerous hazards due to the amount of moving parts, size, high-speed movements, and sharp tools in the equipment. Fortunately, there are solutions and ways to mitigate the risks so employees can continue to work safely.

Spinning parts and tools may seem dangerous and they actually are, if not careful enough. But is the job of a CNC machine operator dangerous? Firstly, machining operations may emit quite a bit of dust and smoke. The dust includes metal . Two primary hazards arise from CNC turning operations: Entanglement and the ejection of parts. Se-rious lacerations, fractures, amputations, or even death can occur if an operator contacts or becomes entangled in or between the tooling or rotating work piece. Safety in CNC environments is essential for users – and for productivity. Consider these 5 points to avoid injury, part failure and downtime. The most dangerous time for a CNC user is when a cutting tool approaches for the first time. Consistently programming rapid approach movements is one way to promote CNC safety. Photo: Getty Images.

The Three Types of Safety Hazards in CNC Machine

Milling machines and computer-numerical-controlled (CNC) mills use moving cutters and/or move stock materials to cut shapes in materials such as metal, wood or plastic. Follow safety precautions when using milling and CNC CNC technology has been a boon for the machining industry and has made working with machines safer for operators, but there are still many dangers in using these modern machines, for both operators and maintainers. This article guides you to the standards that must be followed to ensure a safe working environment.

One of the main safety issues of CNC machining is the potential for machine hazards, such as moving parts, sharp edges, hot surfaces, sparks, chips, and noise. These hazards can.

Vertical machining center hazards. When operating a CNC vertical machine, machinists must be aware of the dangers it poses if not handled correctly and with appropriate supervision. Some of the common vulnerabilities associated with the unsupervised use of a vertical machining center include: CNC machining is dangerous, even for the most experienced metalworking professionals. That’s why safety managers and industrial hygienists should fully understand the nuances of CNC machine operations and the appropriate safety precautions to . Learn about the potential hazards of CNC machines, their safety features, and guidelines that will enable you to safely work with these machines, preventing accidents in the workplace. 1. Noise. 2. Chips. 3. Moving Components or Machinery. 4. Falling Heavy Objects. 5. Heat from the Cutting Process. 1. Safety or Containment Shield. 2. Video Cameras.

CNC machines themselves pose numerous hazards due to the amount of moving parts, size, high-speed movements, and sharp tools in the equipment. Fortunately, there are solutions and ways to mitigate the risks so employees can continue to work safely. Spinning parts and tools may seem dangerous and they actually are, if not careful enough. But is the job of a CNC machine operator dangerous? Firstly, machining operations may emit quite a bit of dust and smoke. The dust includes metal . Two primary hazards arise from CNC turning operations: Entanglement and the ejection of parts. Se-rious lacerations, fractures, amputations, or even death can occur if an operator contacts or becomes entangled in or between the tooling or rotating work piece.

Safety in CNC environments is essential for users – and for productivity. Consider these 5 points to avoid injury, part failure and downtime. The most dangerous time for a CNC user is when a cutting tool approaches for the first time. Consistently programming rapid approach movements is one way to promote CNC safety. Photo: Getty Images.Milling machines and computer-numerical-controlled (CNC) mills use moving cutters and/or move stock materials to cut shapes in materials such as metal, wood or plastic. Follow safety precautions when using milling and CNC CNC technology has been a boon for the machining industry and has made working with machines safer for operators, but there are still many dangers in using these modern machines, for both operators and maintainers. This article guides you to the standards that must be followed to ensure a safe working environment.One of the main safety issues of CNC machining is the potential for machine hazards, such as moving parts, sharp edges, hot surfaces, sparks, chips, and noise. These hazards can.

Safety tips for CNC machinery operation

do metal outlet boxes need to be grounded

do i need to clamp wires in plastic electrical box

Safety and Environmental Issues of CNC Machining

$21.99

cnc machine dangers|Getting CNC machine safety right